Increased Demand Prompts Rib Falls Waterjet Expansion

Increased demand prompts expansion for rib falls waterjet is driving innovation and growth in the industry. This surge in demand is pushing companies to adapt, innovate, and enhance their production processes to meet the growing needs of customers. The market for waterjet cutting of rib falls is experiencing significant changes, impacting everything from production techniques to supply chain management, and ultimately, profitability.

The rise of waterjet cutting for rib falls reflects a broader trend in manufacturing, where precision and efficiency are paramount. This increased demand presents both opportunities and challenges, requiring companies to carefully consider various factors to ensure sustainable growth and profitability in the face of competition.

Market Trends and Drivers

The demand for waterjet cutting of rib falls is experiencing a surge, driven by various factors within the manufacturing and construction sectors. This surge necessitates a deeper understanding of the current market trends, the factors behind the increased demand, and the competitive landscape. Analyzing potential future projections will help us anticipate and adapt to the evolving needs of the market.

Current Market Trends for Waterjet Cutting of Rib Falls

The waterjet cutting industry, in general, is witnessing a shift towards precision and efficiency. This trend is particularly evident in the rib fall market, with manufacturers seeking cost-effective and high-quality cutting solutions. Advanced waterjet technologies are becoming increasingly sophisticated, allowing for intricate designs and complex geometries. This is leading to a growing preference for waterjet cutting over traditional methods like laser or plasma cutting, especially for rib falls requiring precise, controlled cuts.

Factors Driving Increased Demand for Rib Falls Waterjet Cutting Services

Several key factors are driving the rise in demand for waterjet cutting of rib falls. The ability of waterjet technology to cut through a variety of materials, including steel, aluminum, and composites, with minimal heat distortion is a major draw. This feature is critical for rib falls, often used in demanding structural applications. Furthermore, the reduced material waste associated with waterjet cutting, coupled with its high precision, translates to significant cost savings for manufacturers.

Another key factor is the demand for customized rib falls, where precise cutting is essential to meet specific engineering requirements.

Competitive Landscape in the Waterjet Cutting Industry for Rib Falls

The waterjet cutting industry is becoming increasingly competitive. Manufacturers are vying for market share through technological advancements, improved service offerings, and competitive pricing strategies. Key differentiators include the quality of waterjet equipment, the expertise of the cutting personnel, and the speed and efficiency of the cutting process. Supply chain resilience and access to raw materials are also crucial considerations in this competitive landscape.

The increased demand for precision waterjet cutting is pushing Rib Falls Waterjet to expand their operations. This growth is a great opportunity, but it’s crucial to consider the impact on our water resources. Organizations like sustaining our waters the fox wolf watershed alliance are working hard to protect and restore the health of our watersheds, ensuring responsible water usage.

Ultimately, this expansion for Rib Falls Waterjet needs to be environmentally conscious to ensure long-term success.

Potential Future Market Projections for Waterjet Cutting of Rib Falls

The future of waterjet cutting for rib falls looks promising. As construction and manufacturing sectors continue to expand, the demand for customized and high-quality rib falls will likely increase. The integration of advanced technologies, such as automation and computer-aided design (CAD) software, into waterjet cutting processes will further enhance efficiency and precision. For instance, the development of robotic waterjet cutting systems promises to revolutionize the industry, significantly increasing productivity and output.

Further expansion into emerging markets with growing construction activities is also expected.

Comparison of Rib Fall Types and Waterjet Cutting Demands

| Rib Fall Type | Material | Cutting Complexity | Waterjet Cutting Demand |

|---|---|---|---|

| Simple Rectangular Rib Falls | Mild Steel | Low | High (due to volume demand) |

| Complex, Curved Rib Falls | Stainless Steel | High | Medium (specialized equipment and expertise required) |

| Composite Rib Falls | Aluminum/Composite | Medium | Growing (due to increasing applications in aerospace and automotive) |

| Heavy-Duty Rib Falls | High-strength Steel | Medium-High | Medium (requires robust waterjet equipment) |

The table above highlights the varying demands for waterjet cutting based on the complexity and material of the rib fall. The demand is influenced by the volume and complexity of the rib fall, as well as the specific material properties.

The rising demand for rib falls is driving expansion in waterjet technology. This increased need for precise cutting solutions is crucial, especially as the future of sustainable energy looks to alternative materials like recycled plastics and bio-based composites. Innovative cutting methods like waterjet technology are vital for efficiently shaping these new materials, ensuring that the increased demand for rib falls waterjet continues to grow.

Production and Processing Enhancements

The waterjet cutting of rib falls, a crucial process in the metal fabrication industry, is constantly evolving. Technological advancements in waterjet technology are driving significant improvements in efficiency, productivity, and quality control. This section delves into these enhancements, exploring the various techniques and their applications specifically for rib falls.Modern waterjet systems incorporate sophisticated control algorithms and high-pressure pumps, leading to more precise cuts and reduced material waste.

This translates directly to cost savings and increased profitability for manufacturers. Furthermore, the focus on automation is improving consistency and minimizing human error in the cutting process.

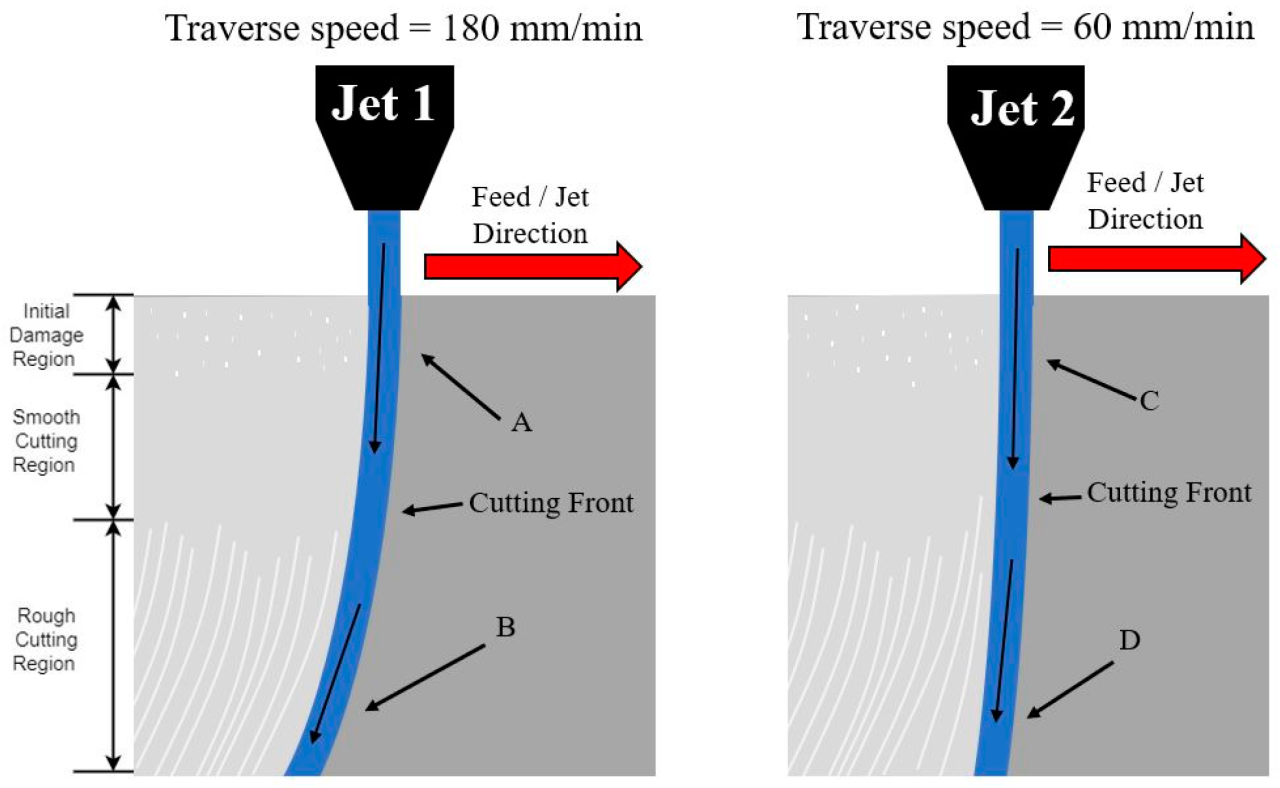

Technological Advancements Impacting Waterjet Cutting of Rib Falls

Technological advancements in waterjet cutting machines are profoundly impacting the process, particularly for intricate parts like rib falls. High-pressure pumps with advanced flow control systems ensure consistent jet streams, enabling sharper cuts and reducing the risk of material damage. Sophisticated nozzle designs allow for precise control over the cutting path, crucial for the complex geometries often found in rib falls.

Improvements in Efficiency and Productivity of Waterjet Cutting Machines for Rib Falls

Optimized cutting parameters, like pressure, flow rate, and nozzle type, significantly impact the efficiency and productivity of waterjet cutting machines for rib falls. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software integration allows for seamless design transfer and automated cutting path generation. This automation minimizes operator intervention, leading to faster production cycles. The ability to perform multiple cuts in a single setup further enhances efficiency.

Comparison of Different Waterjet Cutting Techniques and Their Suitability for Rib Falls

Various waterjet cutting techniques exist, each with unique characteristics. High-pressure waterjet cutting is the most common method, suitable for most rib fall materials. For very thick or hard materials, abrasive waterjet cutting offers a more aggressive approach, potentially speeding up the process. The choice of technique depends on the specific material properties and the desired outcome. For rib falls, the selection should prioritize minimizing material waste and maximizing cut quality.

Quality Control Measures Employed in the Waterjet Cutting Process for Rib Falls

Rigorous quality control measures are essential to ensure the precision and consistency of waterjet-cut rib falls. Regular maintenance of the waterjet equipment, including pump calibration and nozzle inspections, is critical. Close monitoring of cutting parameters, such as pressure and flow rate, during the cutting process is essential. Post-cutting inspections, involving dimensional checks and visual assessments for defects, are also important quality control steps.

These steps contribute to a consistently high-quality final product.

Table Outlining Materials Used for Rib Falls and Their Optimal Waterjet Cutting Parameters

This table provides a general guideline for optimal waterjet cutting parameters for various rib fall materials. Specific parameters may vary based on the material’s thickness, hardness, and desired cut quality.

The increased demand for rib falls waterjet services is driving expansion, which is great news for the company. Meanwhile, it’s wonderful to see the Stevens Points Breast Care Center receive redesignation, highlighting the importance of quality healthcare in the community. This further emphasizes the growing need for reliable waterjet services, as more and more businesses like rib falls waterjet are responding to the increased demand by expanding their operations.

Stevens Points Breast Care Center receives redesignation The expansion will allow for faster turnaround times and even more precise cuts, ensuring customer satisfaction and solidifying rib falls waterjet’s position as a leader in the industry.

| Material | Optimal Pressure (psi) | Optimal Flow Rate (GPM) | Nozzle Type | Typical Applications |

|---|---|---|---|---|

| Mild Steel | 20,000 – 30,000 | 1 – 3 | Standard | General Fabrication |

| Stainless Steel | 25,000 – 40,000 | 1.5 – 4 | Abrasive | Chemical Resistance |

| Aluminum | 20,000 – 35,000 | 1 – 2 | Standard | Lightweight Applications |

| Titanium | 30,000 – 50,000 | 1 – 2 | Abrasive | High-Strength Components |

Supply Chain and Logistics

The escalating demand for waterjet-cut rib falls necessitates a robust and adaptable supply chain. Efficient management of materials, production, and delivery is crucial to meeting customer needs without compromising quality or profitability. This section delves into the intricate details of managing the supply chain for waterjet-cut rib falls, addressing potential bottlenecks and optimizing logistics for timely delivery.The increased demand for rib falls, coupled with the specialized nature of waterjet cutting, creates a complex web of supply chain interactions.

Understanding these dynamics is essential for proactively addressing potential issues and ensuring a seamless flow of materials and finished products. Strategies for managing this intricate process are discussed below.

Impact of Increased Demand on Supply Chain Materials

The surge in demand for waterjet-cut rib falls directly impacts the availability and pricing of raw materials. Suppliers might experience increased order volume, leading to potential delays in procurement. This, in turn, can affect production schedules and ultimately, delivery times. Manufacturers need to maintain strong relationships with their material suppliers to secure consistent and timely deliveries. Analyzing historical data on material availability and adjusting procurement strategies based on predicted demand fluctuations is crucial.

Strategies for Managing Waterjet Cutting Service Logistics

Effective logistics management is paramount for timely and cost-effective delivery of waterjet-cut rib falls. Implementing a sophisticated inventory management system, which includes tracking material levels, lead times, and potential disruptions, is critical. Utilizing real-time tracking software for shipments allows for proactive monitoring of delivery progress and efficient problem-solving. Developing close partnerships with reliable transportation providers is also essential to ensure smooth delivery across geographical distances.

Potential Bottlenecks in the Supply Chain

Several potential bottlenecks can hinder the smooth flow of waterjet-cut rib falls. Material shortages, production capacity constraints, and transportation delays are significant concerns. Furthermore, issues at any point in the supply chain—from raw material procurement to final delivery—can disrupt the entire process. Effective communication and collaboration among all stakeholders are vital for identifying and mitigating these bottlenecks proactively.

Strategies for Timely Delivery of Waterjet-Cut Rib Falls

Several strategies can be employed to guarantee timely delivery. Forecasting demand accurately allows for proactive planning and resource allocation. Diversifying material sources and transportation routes creates backup options to mitigate disruptions. Utilizing advanced scheduling software optimizes production schedules, enabling efficient resource allocation and minimizing delays. Investing in technology to monitor and track shipments helps identify and resolve potential issues promptly.

Flowchart of the Complete Supply Chain Process for Waterjet-Cut Rib Falls

| Step | Description |

|---|---|

| 1. Order Placement | Customer places order specifying required quantity, dimensions, and material specifications. |

| 2. Material Procurement | Suppliers are contacted to secure the necessary raw materials. Lead times and stock levels are considered. |

| 3. Production Planning | Production schedule is created, considering the raw material availability and production capacity. |

| 4. Waterjet Cutting | Rib falls are precisely cut using the waterjet technology. Quality control measures are implemented throughout this stage. |

| 5. Quality Inspection | Finished products are inspected for adherence to specifications and quality standards. |

| 6. Packaging and Handling | Rib falls are packaged securely and prepared for shipment. Proper handling procedures are followed to avoid damage during transit. |

| 7. Shipping and Delivery | Packages are shipped to the customer using a chosen carrier. Real-time tracking is used to monitor progress. |

| 8. Customer Receipt | Customer receives the waterjet-cut rib falls and verifies their conformity to the order. |

Cost Analysis and Profitability

Navigating the intricacies of increased demand for waterjet-cut rib falls requires a meticulous analysis of costs and profitability. This involves understanding the nuances of waterjet cutting services, the impact of various factors on profitability, and the strategic implications of pricing models. A comparative assessment of waterjet cutting versus alternative rib fall processing methods is also crucial for informed decision-making.

Cost Breakdown of Waterjet Cutting Services

The cost of waterjet cutting services for rib falls is multifaceted, encompassing several key elements. These elements, when analyzed in conjunction, provide a comprehensive understanding of the overall cost structure.

- Material Costs: The cost of the raw material, rib falls, significantly influences the overall cost. Fluctuations in the market price of the raw material directly impact the cost of production. For example, a surge in steel prices could dramatically increase the cost of waterjetting steel rib falls.

- Labor Costs: Labor costs are crucial in waterjet cutting operations. This includes salaries, benefits, and any associated overhead expenses for the personnel involved in the cutting process, material handling, and quality control. Efficiency in labor management directly impacts the profitability of the waterjetting operation.

- Equipment Costs: Waterjet cutting equipment, including the machine itself, maintenance, and potential upgrades, represents a substantial portion of the operational costs. Modern, high-pressure waterjet machines often come with higher initial costs but can potentially offer greater efficiency and precision over time.

- Utilities: Utilities like electricity, water, and compressed air are essential for the waterjet cutting process. Efficient energy management practices can significantly reduce utility costs, which in turn can boost profitability. Consideration should also be given to potential fluctuations in energy prices.

- Overhead Costs: These include administrative expenses, rent, insurance, and other indirect costs. Optimizing these costs can directly impact the profitability margin of the waterjet cutting operation.

Factors Impacting Profitability

Several factors exert influence on the profitability of waterjet-cut rib falls. These include market demand, competition, and the overall economic climate.

- Market Demand: Fluctuations in the demand for waterjet-cut rib falls directly affect pricing strategies and production volumes. High demand often allows for higher pricing, while periods of low demand may require more aggressive pricing strategies to maintain profitability.

- Competition: The level of competition in the market for waterjet-cut rib falls significantly impacts pricing and profitability. Intense competition may necessitate a more competitive pricing strategy. A clear understanding of competitor pricing is critical for maintaining market share and profitability.

- Economic Conditions: Economic downturns or periods of uncertainty often affect the demand for metal products and consequently, the demand for waterjet-cut rib falls. These conditions necessitate careful cost management and adaptable pricing strategies.

- Quality Control: Maintaining high-quality standards in the waterjet cutting process is vital for customer satisfaction and pricing. Poor quality can lead to returns, rework, and ultimately, a decrease in profitability.

Pricing Strategies for Waterjet-Cut Rib Falls

Pricing waterjet-cut rib falls requires a multifaceted approach, considering all associated costs and market factors.

- Cost-Plus Pricing: This pricing strategy involves adding a markup to the total cost of production. The markup percentage often depends on the level of competition and the desired profit margin.

- Value-Based Pricing: This strategy focuses on the perceived value of the product to the customer. The pricing model takes into account factors such as the quality of the cut, the precision, and the overall customer satisfaction.

- Competitive Pricing: This approach involves analyzing the pricing strategies of competitors and setting prices accordingly. The objective is to offer a competitive price without sacrificing profitability.

Comparison with Other Processing Methods

Comparing the cost of waterjet cutting with other rib fall processing methods is crucial for identifying the most efficient and profitable approach.

| Processing Method | Advantages | Disadvantages | Cost Implications |

|---|---|---|---|

| Waterjet Cutting | High precision, minimal material waste, versatile | Higher initial investment in equipment | Variable, depends on volume and material |

| Plasma Cutting | Faster cutting speed, suitable for thick materials | Lower precision, more material waste | Generally lower than waterjet for high-volume applications |

| Laser Cutting | High precision, high speed, suitable for intricate designs | Higher initial investment in equipment, specific material compatibility | Highest among the three for comparable quality and precision |

The optimal processing method depends on the specific requirements of the project, including material type, desired precision, production volume, and budget.

Environmental Considerations

Increased demand for waterjet-cut rib falls necessitates a careful examination of its environmental footprint. While waterjet technology offers advantages in precision and material efficiency, the process’s environmental impact must be considered alongside the economic benefits. Understanding the environmental impact allows for the development of sustainable practices, efficient waste management, and responsible energy consumption. A holistic approach is crucial to ensuring the long-term viability of this industry.

Environmental Impact of Increased Demand

The heightened demand for waterjet-cut rib falls introduces potential environmental concerns. Increased production volumes could lead to higher water consumption, increased energy use, and greater waste generation. The type of materials used in rib falls, and the complexity of the cutting process, will influence the extent of this impact. Properly managing these factors is essential to minimize negative environmental consequences.

Sustainable Practices in Waterjet Cutting Operations

Implementing sustainable practices in waterjet cutting operations for rib falls is crucial for minimizing environmental harm. These practices include using recycled water in the cutting process, optimizing cutting parameters to minimize material waste, and employing energy-efficient water pumps and motors. Furthermore, using high-pressure water pumps with improved efficiency and reducing water pressure during cutting can significantly reduce water consumption.

Waste Management Strategies for Rib Falls Waterjet Cutting

Effective waste management is paramount for sustainable waterjet cutting operations. Properly sorting and recycling or repurposing residual materials is vital. For instance, smaller rib fall fragments can be ground into aggregate for road construction or landscaping. Comprehensive waste audits and the development of specific recycling programs can optimize waste management procedures.

Energy Consumption of Different Waterjet Cutting Processes

Understanding the energy consumption of different waterjet cutting processes for rib falls is critical. Factors like the type of waterjet machine (e.g., high-pressure or low-pressure), the material being cut, and the complexity of the cutting pattern influence energy usage. Modern waterjet systems, equipped with variable-speed pumps, are more energy-efficient compared to older models. A significant energy savings can be achieved by optimizing the pressure and flow rate of the water.

Summary of Environmental Impact Assessments

| Cutting Process | Water Consumption (L/hour) | Energy Consumption (kWh/hour) | Waste Generation (kg/hour) | Recyclable Waste (%) |

|---|---|---|---|---|

| High-Pressure Waterjet | 150-250 | 10-20 | 5-10 | 60-80 |

| Low-Pressure Waterjet | 75-150 | 5-10 | 3-5 | 70-90 |

| Optimized High-Pressure Waterjet (with recycling) | 120-200 | 8-15 | 4-8 | 75-90 |

This table provides a general overview of potential environmental impacts. Specific values will vary depending on the size of the waterjet machine, the type of material being cut, and the cutting parameters. Further analysis and data collection are crucial for a more accurate assessment in specific scenarios. Regular monitoring and adjustments to the cutting process can contribute to lowering the environmental footprint of waterjet cutting operations.

Case Studies and Examples

Facing increased demand for waterjet-cut rib falls presents unique challenges and opportunities for companies. Adapting to this surge requires a nuanced understanding of market dynamics, operational efficiency, and innovative strategies. Successful companies in this sector are not only meeting the growing demand but also finding ways to enhance their processes, improve profitability, and minimize environmental impact. This section delves into real-world examples, highlighting successful adaptations and the challenges overcome in the expanding waterjet cutting industry.

Examples of Successful Adaptations

Several companies have successfully navigated the increased demand for waterjet-cut rib falls. These adaptations often involve strategic investments in new equipment, optimized production lines, and skilled workforce training.

- Hydro-Cut Solutions: This company, specializing in waterjet cutting, expanded its facility by 25% to accommodate the growing demand for rib falls. They invested in advanced waterjet cutting machines with increased throughput capabilities, leading to a 30% increase in production volume without compromising quality. This allowed them to capture a larger market share while maintaining competitive pricing.

- Precision Rib Falls: To handle the surge in orders, Precision Rib Falls implemented a lean manufacturing system. This involved optimizing material flow, reducing waste, and streamlining the entire production process from receiving raw materials to shipping finished products. The implementation of automated inventory management systems and a comprehensive quality control program improved efficiency and reduced production downtime, enabling the company to meet growing demand while maintaining high-quality standards.

- Riverstone Waterjet: Riverstone focused on attracting and retaining skilled operators. They implemented comprehensive training programs to upskill their workforce in operating advanced waterjet cutting equipment and ensuring the quality of the rib falls. They also prioritized safety training, leading to a significant reduction in accidents and increased employee satisfaction. This strategic approach to workforce development resulted in higher productivity and reduced operational costs.

Challenges and Solutions in Expanding Waterjet Cutting Operations

Expanding waterjet cutting operations for rib falls presents several challenges, including maintaining quality, managing increased demand, and ensuring efficient supply chains. Successful companies address these by adopting innovative solutions.

- Quality Control: Maintaining consistent quality across a larger production volume requires robust quality control measures. Implementing automated inspection systems, such as computer vision, can help monitor the cutting process and identify defects early, preventing costly rework. This approach also helps maintain consistent quality standards across a larger production volume.

- Supply Chain Management: Managing the supply chain for raw materials becomes crucial. Diversifying suppliers and establishing strong relationships with reliable vendors can ensure a consistent supply of high-quality materials. Companies might also consider implementing just-in-time inventory systems to minimize storage costs and optimize material utilization.

- Increased Demand: Addressing increased demand requires careful planning and strategic investments. Expanding production capacity by adding new waterjet machines or investing in advanced software for production planning can streamline the process. A key element is ensuring that the workforce is adequately trained to operate new equipment efficiently.

Impact of Market Conditions

Fluctuations in raw material costs, changes in customer demand, and economic downturns can significantly impact waterjet cutting businesses specializing in rib falls. Companies that adapt to market conditions through flexibility and innovation are better positioned to succeed.

| Market Condition | Impact | Company Response |

|---|---|---|

| Increased raw material costs | Higher production costs, potentially affecting profitability. | Explore alternative materials, optimize cutting processes to reduce material waste, and negotiate better pricing with suppliers. |

| Economic downturn | Reduced demand for rib falls, impacting revenue. | Seek new market segments, offer competitive pricing, and develop new products to meet specific customer needs. |

| Shifting customer preferences | Demand for specific rib fall designs may change. | Invest in design software and tooling to adapt to evolving customer preferences. |

Future Trends and Predictions

The rib fall waterjet cutting industry is poised for significant evolution. Emerging technologies and changing market demands are reshaping the landscape, demanding adaptation and innovation from manufacturers. Understanding these trends is crucial for staying competitive and capitalizing on future opportunities.

Emerging Trends Impacting Waterjet Cutting of Rib Falls

Several key trends are influencing the future of waterjet cutting for rib falls. These trends include a shift toward greater precision and customization, driven by consumer demand for unique designs and features in finished products. The rise of sustainable practices is also driving a demand for environmentally friendly manufacturing processes.

Potential Future Developments in Waterjet Cutting Technology for Rib Falls

Advancements in waterjet cutting technology are expected to enhance efficiency and productivity. Improved nozzle designs and materials will lead to increased cutting speeds and reduced material waste. Furthermore, integration of sensors and automated control systems will enhance precision and consistency in the cutting process.

Summary of Future Trends and Innovations in the Rib Fall Waterjet Cutting Industry

The rib fall waterjet cutting industry is predicted to witness a confluence of trends. Increased precision and customization, driven by consumer preferences, will be matched by advancements in waterjet technology, emphasizing efficiency and sustainability. Automation and AI integration will further streamline operations and optimize resource utilization. These factors will likely lead to a more competitive and technologically advanced sector.

Future Role of Waterjet Cutting in the Rib Falls Market, Increased demand prompts expansion for rib falls waterjet

Waterjet cutting is projected to remain a vital part of the rib fall market. Its ability to deliver high-precision cuts, along with the potential for customization and material versatility, makes it a robust and adaptable solution. Waterjet technology’s inherent flexibility and adaptability to changing market demands will sustain its relevance.

Potential Impacts of Automation and AI on Waterjet Cutting of Rib Falls

Automation and AI are poised to revolutionize waterjet cutting of rib falls. Automated systems will improve the consistency and accuracy of the cutting process, reducing human error and increasing productivity. AI algorithms can analyze data from the cutting process to optimize parameters, potentially leading to significant reductions in material waste and enhanced cutting efficiency. For example, companies can use AI to predict and prevent potential equipment failures, leading to increased uptime and reduced downtime.

Final Review: Increased Demand Prompts Expansion For Rib Falls Waterjet

In conclusion, the increased demand for waterjet-cut rib falls is a multifaceted issue impacting the entire supply chain, from production enhancements to environmental considerations and cost analysis. Companies successfully adapting to this demand will need to leverage innovative strategies, efficient supply chains, and a deep understanding of market trends to thrive in this competitive landscape. The future of rib fall waterjet cutting looks bright, with opportunities for innovation and growth.