Dairy Waste Renewable Energy Solutions

Dairy waste renewable energy offers a sustainable path to harnessing the potential of agricultural byproducts. From manure to whey, this resource can be transformed into valuable energy sources, significantly reducing environmental impact and creating economic opportunities.

This exploration delves into the composition of dairy waste, its environmental impact when left untreated, and the various methods for its management. We’ll examine the technical processes for converting dairy waste into renewable energy, including biogas and biofuel production, and analyze the economic and social implications of this transition. Finally, we’ll assess the environmental benefits and potential risks, and discuss the future of this innovative approach to sustainable dairy farming.

Introduction to Dairy Waste

Dairy farming, a vital component of global food production, generates substantial amounts of waste. This waste, often overlooked, presents significant environmental challenges if not managed properly. Understanding the composition and sources of this waste, along with its impact and current management practices, is crucial for sustainable agricultural practices.Dairy waste encompasses a range of byproducts, each with unique characteristics and implications for the environment.

Untreated dairy waste can lead to water contamination, air pollution, and the spread of pathogens, negatively impacting both human health and the surrounding ecosystem.

Dairy Waste Composition and Sources

Dairy waste encompasses a diverse array of materials. Manure, a primary byproduct of livestock, is rich in organic matter and nutrients. Whey, a byproduct of cheese production, is a liquid byproduct with high concentrations of lactose and other proteins. Wastewater, generated from various dairy operations, often contains a complex mixture of organic matter, nutrients, and potentially harmful substances.

Understanding the specific composition of each waste stream is critical for developing effective management strategies.

Environmental Impact of Untreated Dairy Waste

Untreated dairy waste poses significant environmental threats. Runoff from improperly managed manure fields can contaminate water sources with harmful pathogens and excess nutrients, leading to eutrophication and algal blooms. Improperly managed whey disposal can result in odour pollution and soil contamination. The release of greenhouse gases, like methane, from decomposing organic matter in manure contributes to climate change.

This highlights the urgency of developing effective waste management strategies.

Current Dairy Waste Management Methods

Various methods are currently employed to manage dairy waste. These range from traditional approaches like composting to innovative technologies such as anaerobic digestion. Each method has its own set of advantages and disadvantages, which need to be carefully evaluated in the context of specific farm operations and environmental regulations.

Table of Dairy Waste Management Strategies

| Method | Pros | Cons |

|---|---|---|

| Anaerobic Digestion | Produces biogas (methane and carbon dioxide) that can be used as a renewable energy source. Reduces the volume of waste significantly. Improves nutrient recovery for use as fertilizer. | Requires specialized equipment and infrastructure. May not be economically feasible for smaller farms. Can produce odours if not properly managed. |

| Composting | Transforms organic waste into a valuable soil amendment. Relatively low cost and readily available technology. | Can be slow. Requires careful management to prevent pathogen contamination. May not be suitable for all types of dairy waste. |

| Land Application | Utilizes manure as fertilizer, increasing soil fertility. Relatively low cost. | Can lead to nutrient runoff if not managed properly, contaminating water sources. Requires careful consideration of soil type and application rates to avoid environmental damage. Can cause odours. |

| Incineration | Completely eliminates waste volume. Reduces pathogens. | Generates air pollution, releasing potentially harmful pollutants. High energy consumption and cost. Not environmentally friendly. |

Dairy Waste as a Renewable Energy Source

Dairy waste, a byproduct of the dairy industry, presents a significant opportunity for generating renewable energy. The sheer volume of this waste, coupled with its organic composition, makes it a valuable resource. Converting this waste into usable energy not only reduces environmental impact but also creates economic opportunities. This sustainable approach aligns with the global push towards a greener future and demonstrates a concrete application of circular economy principles.The potential of dairy waste to generate renewable energy is multifaceted, extending beyond simple waste disposal.

The organic matter within dairy waste can be converted into valuable energy sources like biogas and biofuels, offering a sustainable alternative to fossil fuels. By effectively utilizing this resource, the dairy industry can significantly reduce its carbon footprint and contribute to a more environmentally friendly production process.

Potential Renewable Energy Sources

Dairy waste, rich in organic matter, is a fertile ground for generating various forms of renewable energy. Biogas, a versatile fuel produced from anaerobic digestion, is a prime example. Biogas is a renewable energy source that can be used to generate electricity, heat, and even compressed natural gas (CNG). Additionally, biofuels, derived from the conversion of dairy waste into liquid fuels, are gaining traction as a viable alternative to traditional fossil fuels.

The feasibility of these energy sources depends on the specific composition of the dairy waste and the technical processes employed.

Key Components Suitable for Energy Production

Several key components within dairy waste are suitable for energy production. These include manure, whey, and other byproducts. Manure, a significant component of dairy waste, is rich in organic matter and easily digestible by anaerobic digestion processes. Whey, a byproduct of cheese production, also contains significant amounts of sugars and proteins, making it suitable for biofuel production.

The composition and concentration of these components directly influence the type and efficiency of the energy conversion process.

Technical Processes for Conversion

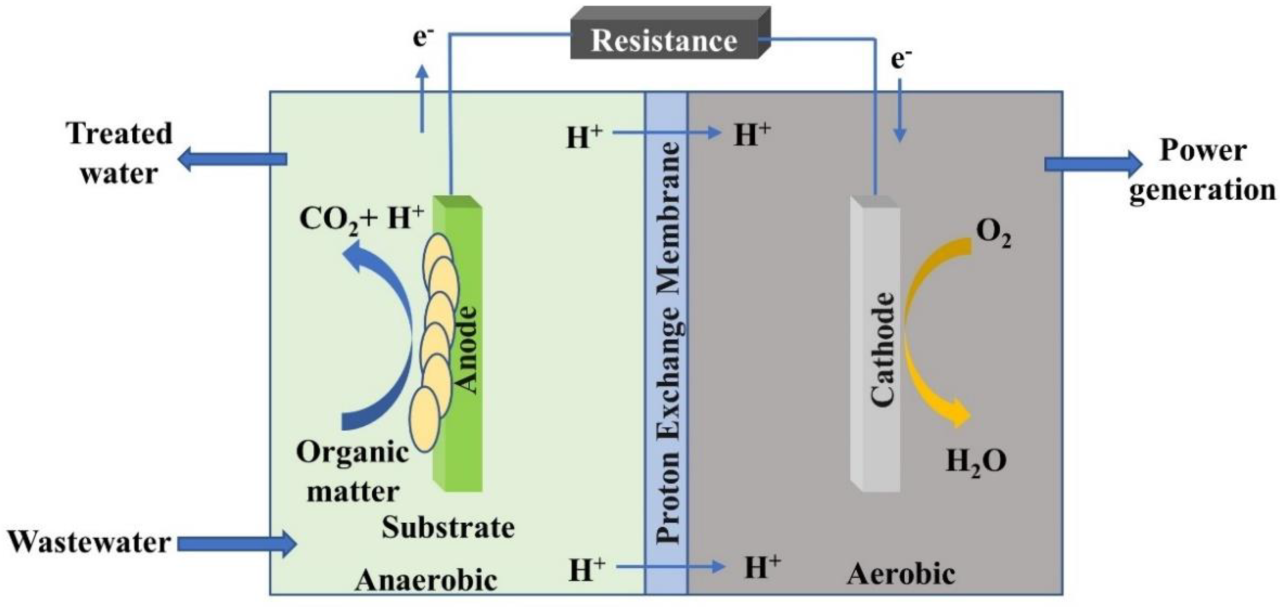

The conversion of dairy waste into renewable energy involves specific technical processes. Anaerobic digestion is a key technology for biogas production. In this process, microorganisms break down organic matter in the absence of oxygen, producing biogas, primarily methane and carbon dioxide. Biofuel production, on the other hand, involves processes like transesterification, which convert lipids and fats into biodiesel.

The selection of the appropriate conversion process depends on the desired end-product and the specific composition of the dairy waste.

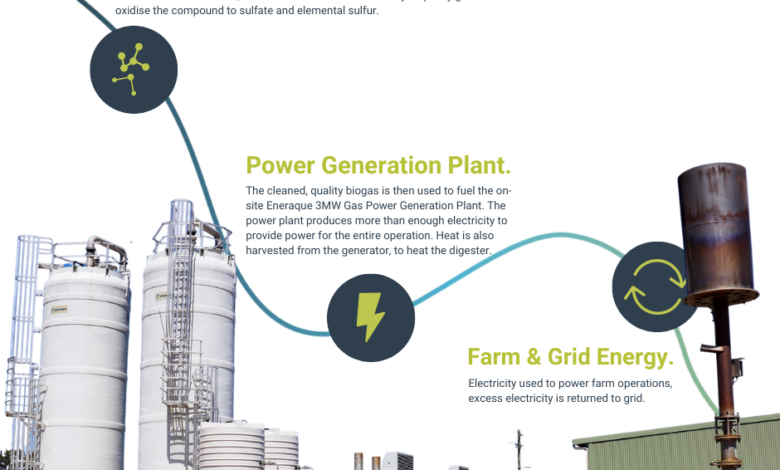

Process Flow Diagram

The following diagram illustrates a simplified process flow for converting dairy waste into energy, specifically biogas:

+-----------------+ +-----------------+ +-----------------+ | Dairy Waste | --> | Anaerobic Digester | --> | Biogas Treatment | +-----------------+ +-----------------+ +-----------------+ | | | (e.g., slurry) | | (e.g., upgrading) | | (Manure, Whey) | | ...| | ... | | | | Microbes | | (e.g., removing impurities)| +-----------------+ +-----------------+ +-----------------+ | | V | +-----------------+ | | Biogas Collection| | +-----------------+ V +-----------------+ | Energy Utilization| +-----------------+ | (Electricity, heat)| +-----------------+

This diagram Artikels the basic steps from collecting dairy waste to utilizing the generated biogas.

Further refinements and modifications are possible depending on specific industrial needs and conditions.

Biogas Production from Dairy Waste

Dairy farming, while vital for food production, generates significant organic waste. This waste, if managed properly, can be a valuable resource, especially in the form of biogas. Biogas production offers a sustainable solution for energy generation and waste management, while reducing environmental impact. The process involves harnessing the anaerobic digestion of dairy waste, converting it into a usable energy source.

The anaerobic digestion process, a naturally occurring biological process, breaks down organic matter in the absence of oxygen. This decomposition is facilitated by microorganisms that convert complex organic compounds in the dairy waste into biogas, primarily methane (CH₄) and carbon dioxide (CO₂). The resulting biogas can be used as a clean-burning fuel source for electricity generation, heating, or cooking.

Biogas Production Process

The process of biogas production from dairy waste typically involves several stages:

- Collection and Pre-treatment: Dairy waste, encompassing manure, whey, and other byproducts, is collected and pre-treated to optimize its suitability for digestion. This may include size reduction, mixing, and pH adjustment to create a favorable environment for microbial activity. Effective pre-treatment is crucial for efficient digestion.

- Anaerobic Digestion: The pre-treated waste is introduced into a digester, a sealed tank where anaerobic microorganisms thrive. These microorganisms decompose the organic matter, producing biogas. The digester is typically maintained at a specific temperature and pH to promote optimal microbial activity.

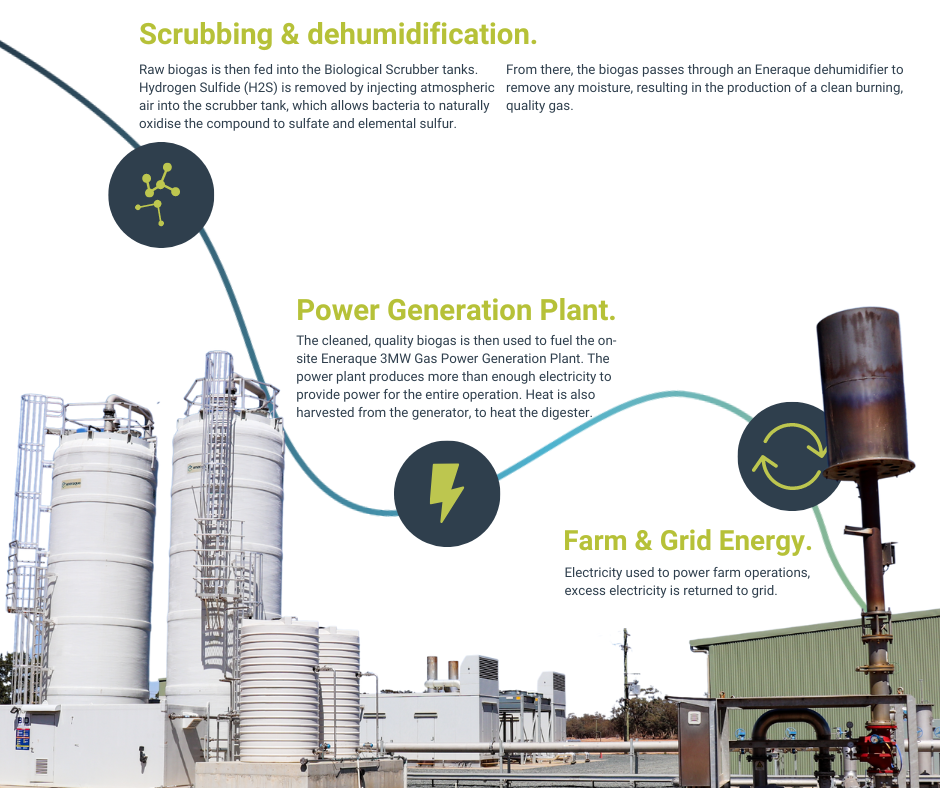

- Biogas Upgrading: The biogas produced is typically a mixture of methane and carbon dioxide. This mixture needs to be upgraded to increase the methane content for more efficient use. Upgrading techniques, such as pressure swing adsorption or membrane separation, remove impurities to achieve a higher purity of methane.

- Energy Generation: The upgraded biogas can be directly used as fuel in engines or turbines to generate electricity. It can also be used for heating applications or compressed for transportation fuel.

Factors Affecting Biogas Yield

Several factors influence the amount of biogas generated from dairy waste:

- Waste Composition: The specific composition of the dairy waste, including the proportions of manure, whey, and other byproducts, significantly impacts the biogas yield. Variations in the organic matter content and the presence of inhibiting substances can affect the digestion process.

- Digestion Temperature: The temperature at which the anaerobic digestion process takes place affects the microbial activity and, consequently, the biogas production rate. Mesophilic (35-40°C) and thermophilic (50-55°C) conditions are commonly employed.

- Digestion Time: The duration of the digestion process affects the extent of the decomposition of organic matter and, thus, the biogas yield. Longer digestion times generally lead to higher biogas yields, but also increase operational costs.

- pH Level: The pH of the digester plays a crucial role in the activity of the microorganisms. Optimal pH levels must be maintained to ensure efficient decomposition and biogas production.

Benefits of Biogas as a Renewable Energy Source

Biogas, derived from dairy waste, offers numerous advantages:

- Renewable Energy Source: Dairy waste is a readily available and renewable resource, ensuring a sustainable energy source.

- Waste Management: Anaerobic digestion effectively manages organic waste, reducing the environmental burden of landfill disposal and minimizing the release of greenhouse gases.

- Reduced Greenhouse Gas Emissions: Biogas production can significantly reduce greenhouse gas emissions compared to traditional fossil fuels. Methane, a potent greenhouse gas, is captured and utilized as an energy source.

- Energy Security: Biogas production can contribute to energy security by reducing reliance on imported fossil fuels.

Comparison of Biogas Production from Different Dairy Waste Types

Different dairy waste types exhibit varying biogas yields and efficiencies.

| Waste Type | Biogas Yield (m³/ton) | Efficiency (%) |

|---|---|---|

| Manure (cow) | 100-200 | 60-75 |

| Whey | 150-250 | 70-80 |

| Mixed Dairy Waste | 120-220 | 65-78 |

Note: These values are approximate and can vary based on factors like waste composition, digestion conditions, and pre-treatment methods.

Biofuel Production from Dairy Waste

Turning dairy waste into biofuels like biodiesel offers a sustainable solution to energy needs and waste management. This approach reduces reliance on fossil fuels, mitigates environmental impact, and creates economic opportunities. The process involves converting organic matter into usable fuel, a valuable application of waste recycling.

Converting dairy waste into biofuels, specifically biodiesel, involves several steps, each crucial for efficiency and environmental considerations. This process has the potential to significantly reduce our environmental footprint by diverting waste from landfills and generating renewable energy.

Biodiesel Production from Dairy Waste: A Step-by-Step Guide

The conversion of dairy waste into biodiesel typically follows a transesterification process. This involves reacting the waste with an alcohol, usually methanol, in the presence of a catalyst. This chemical reaction breaks down the lipids in the waste into fatty acid methyl esters (FAMEs), which form the basis of biodiesel.

- Collection and Pre-treatment: Dairy waste, including manure, whey, and other byproducts, is collected and pre-treated to remove impurities and increase the efficiency of the next stages. This pre-treatment may include separating solids from liquids or adjusting the pH to optimize the subsequent reaction.

- Lipid Extraction: The lipids present in the dairy waste are extracted through various methods, such as centrifugation or solvent extraction. The goal is to isolate the lipids for subsequent conversion.

- Transesterification: The extracted lipids are reacted with methanol in the presence of a catalyst (typically a base catalyst like sodium hydroxide). This chemical reaction converts the lipids into fatty acid methyl esters (FAMEs), the primary components of biodiesel.

- Separation and Purification: The FAMEs are separated from the glycerol byproduct and the catalyst residue. Purification steps remove any remaining impurities to ensure the biodiesel meets quality standards.

- Biodiesel Characterization and Testing: The produced biodiesel is characterized and tested to ensure its quality, viscosity, and other properties meet the required standards for use in diesel engines.

Challenges and Limitations of Biofuel Production from Dairy Waste

Several challenges hinder the widespread adoption of biofuel production from dairy waste. Economic viability, technological hurdles, and environmental concerns are key factors.

- Cost of Production: The cost of raw materials, catalysts, and the entire process can be a significant barrier. Efficient methods to extract lipids and reduce catalyst usage are crucial to reduce production costs.

- Scalability Issues: The production process needs to be scalable to handle large volumes of dairy waste effectively. This requires significant investment in infrastructure and technology.

- Environmental Impact: While biofuels are considered more sustainable than fossil fuels, certain production methods can have negative environmental impacts if not managed carefully. Proper waste management and carbon footprint analysis are essential.

- Feedstock Variability: The composition of dairy waste can vary depending on the type of dairy operation and season, impacting the efficiency of the process.

Feasibility of Producing Different Biofuels from Dairy Waste

The feasibility of producing different biofuels from dairy waste depends on the specific feedstock characteristics and the desired product.

- Biodiesel: Biodiesel is often considered the most feasible biofuel to produce from dairy waste due to the readily available lipids in the waste.

- Bioethanol: Producing bioethanol from dairy waste is less straightforward compared to biodiesel, as the necessary sugars or starches are not always present in significant quantities in dairy waste.

Environmental Impacts of Different Biofuel Production Processes

This table Artikels the potential environmental impacts of different biofuel production processes from dairy waste.

| Process | Greenhouse Gas Emissions (kg CO2e/MJ) | Water Consumption (m³/MJ) |

|---|---|---|

| Biodiesel from Dairy Waste (Optimized) | 1.5 | 0.05 |

| Biodiesel from Vegetable Oil (Comparison) | 1.2 | 0.04 |

Economic and Social Impacts

Turning dairy waste into renewable energy isn’t just about saving the planet; it’s about creating a more sustainable and profitable future for the entire dairy industry. This shift offers exciting economic possibilities, not only for the farms themselves, but also for the wider community. The potential for job creation, reduced environmental impact, and increased profitability makes this a truly multifaceted opportunity.

The economic viability of this process depends heavily on factors like the cost of feedstock, technology used, and market demand for the generated energy. However, preliminary studies and existing projects suggest that, under the right circumstances, dairy waste-to-energy can be a profitable venture.

Economic Viability

Converting dairy waste into renewable energy sources can generate substantial economic benefits for dairy farms. Reduced reliance on fossil fuels, coupled with the potential for selling excess energy or renewable energy credits, can significantly lower operating costs. Additionally, the sale of biogas or biofuels produced from dairy waste can generate revenue streams, increasing farm profitability. This can lead to a positive feedback loop, where reduced operating costs further incentivize the adoption of these sustainable practices.

Job Creation Opportunities

The dairy waste-to-energy sector presents a unique opportunity for job creation at various levels. From technicians and engineers to maintenance personnel and project managers, the implementation and operation of biogas plants and biofuel facilities will require a skilled workforce. Furthermore, the increased demand for skilled labor in this sector can spur educational initiatives and training programs, fostering a more sustainable and technologically advanced agricultural workforce.

This includes creating jobs in the design, construction, and maintenance of the facilities, as well as jobs in the associated distribution and marketing of the produced energy.

Social Benefits

The social benefits of converting dairy waste into renewable energy are numerous. Reducing reliance on fossil fuels lowers the carbon footprint of the dairy industry, contributing to a healthier environment and mitigating the effects of climate change. This improved environmental impact also fosters public support for dairy farms, improving their image and relationships with the surrounding community. The improved community image and reduced pollution also contribute to a more positive perception of the dairy industry.

Examples of Successful Projects

Several successful dairy waste-to-energy projects have already demonstrated the feasibility and profitability of this approach. For instance, a dairy farm in the Netherlands successfully implemented a biogas plant, significantly reducing their operating costs and generating substantial revenue from the sale of biogas. Other farms have implemented similar projects, showing that dairy waste-to-energy can be a viable option for a wide range of farms, regardless of size or location.

Importance of Sustainable Practices

“Sustainable practices in dairy farming are not just environmentally sound, but economically beneficial as well. Investing in renewable energy solutions from dairy waste not only reduces our reliance on finite resources but also paves the way for a more resilient and profitable future for the dairy industry.”

Environmental Considerations

Harnessing dairy waste for renewable energy offers significant environmental advantages, but careful consideration of various management strategies is crucial. Different methods of processing dairy waste, from traditional land application to advanced biogas production, have varying impacts on the environment. Understanding these impacts is vital for implementing sustainable practices within the dairy industry.

Turning dairy waste into renewable energy is a fantastic idea, but we also need to think about the broader impact on our water systems. The Fox Wolf Watershed Alliance, for example, is a fantastic organization dedicated to sustaining our waters, and their work highlights the crucial link between responsible waste management and healthy ecosystems. Ultimately, innovative solutions like converting dairy waste into energy are crucial to a sustainable future, especially when paired with efforts to protect our water sources like those championed by sustaining our waters the fox wolf watershed alliance.

Environmental Benefits of Using Dairy Waste for Renewable Energy

Utilizing dairy waste for renewable energy reduces reliance on fossil fuels, lowering greenhouse gas emissions. By diverting this waste from landfills, where it can decompose and release methane (a potent greenhouse gas), we can significantly contribute to mitigating climate change. Furthermore, the energy produced can displace the need for energy derived from non-renewable sources, lessening the environmental burden associated with their extraction and processing.

This approach promotes a circular economy, minimizing waste and maximizing resource utilization within the agricultural sector.

Turning dairy waste into renewable energy is a fantastic idea, right? It’s great to see innovative solutions emerging for waste management. Meanwhile, the Stevens Points Breast Care Center is getting a much-needed upgrade, which is fantastic news for the community. Stevens Points Breast Care Center receives redesignation This kind of investment highlights the importance of community support and resourcefulness, which can also be applied to creating sustainable solutions for dairy waste, like biogas production.

Environmental Impacts of Different Dairy Waste Management Strategies

Various strategies for managing dairy waste have distinct environmental footprints. Traditional land application, while seemingly simple, can lead to soil and water contamination if not properly managed. Excessive nutrient runoff can cause eutrophication in nearby water bodies, harming aquatic ecosystems. Improperly managed composting can generate unpleasant odors and potentially release harmful pathogens into the environment. Landfilling, while a common practice, is often unsustainable due to the significant methane emissions generated during decomposition.

In contrast, biogas production, when implemented correctly, can minimize these negative impacts, offering a more environmentally friendly solution.

Comparison of Environmental Footprints of Different Renewable Energy Sources Derived from Dairy Waste

The environmental footprint of different renewable energy sources derived from dairy waste varies. For example, biogas production, with its potential to capture and utilize methane, can significantly reduce greenhouse gas emissions compared to landfilling. However, the efficiency of biogas production varies based on factors like the specific waste composition, digester technology, and overall management practices. Biofuel production, another potential avenue, can have different environmental impacts depending on the specific feedstock used and the processing methods employed.

Turning dairy waste into renewable energy is a fantastic idea, and it’s definitely a step in the right direction. The future of sustainable energy looks to alternative materials like this, exploring innovative solutions to traditional energy sources. the future of sustainable energy looks to alternative materials is key to tackling the challenge of finding environmentally friendly, sustainable sources.

This approach to utilizing dairy waste as a renewable energy source is a promising path forward.

Comparing these footprints requires a thorough life-cycle assessment that accounts for the entire process from waste collection to energy production.

Potential Environmental Risks Associated with the Production of Renewable Energy from Dairy Waste

Potential environmental risks associated with renewable energy production from dairy waste include the possibility of nutrient runoff from processing facilities, potential contamination from pathogens, and the need for careful consideration of land use changes. These potential risks can be mitigated through proper site selection, the implementation of stringent environmental regulations, and adherence to best management practices. Proper waste handling and treatment facilities are essential to prevent contamination and minimize any negative environmental impacts.

Importance of Responsible Waste Management in the Dairy Industry

Responsible waste management is crucial for the dairy industry’s long-term sustainability. Implementing environmentally sound practices is not only a moral imperative but also a strategic necessity. Proactive management of dairy waste can prevent negative environmental impacts, promote resource efficiency, and enhance the industry’s public image. Adopting sustainable practices fosters a positive relationship with the surrounding environment and the communities impacted by dairy operations.

By investing in responsible waste management, the dairy industry can contribute to a healthier planet and a more prosperous future.

Future Trends and Research: Dairy Waste Renewable Energy

The future of dairy waste utilization for renewable energy hinges on innovative solutions that address the challenges and capitalize on the opportunities presented by this abundant resource. Current research and emerging trends are paving the way for more sustainable and efficient processes, promising a significant leap forward in the circular economy.

Emerging Trends in Dairy Waste Utilization, Dairy waste renewable energy

Several trends are shaping the future of dairy waste management, driven by a growing awareness of environmental concerns and economic incentives. These include the increasing interest in anaerobic digestion for biogas production, the development of advanced biofuel technologies, and the exploration of combined heat and power (CHP) systems. The focus is shifting from simply disposing of waste to extracting valuable resources and energy.

Areas Requiring Further Research

Further research is crucial to optimizing the efficiency and sustainability of dairy waste conversion processes. Key areas include enhancing the digestibility of complex dairy components in anaerobic digestion, developing cost-effective pre-treatment methods for recalcitrant materials, and improving the scalability of biofuel production technologies for widespread implementation. Research should also investigate the long-term environmental impacts of these processes and explore the potential of novel microbial consortia for enhanced bioconversion.

Technological Advancements in Dairy Waste Conversion

Technological advancements are critical for boosting the efficiency of dairy waste conversion processes. This includes the development of advanced anaerobic digestion systems with optimized conditions for higher methane yields. Further development of enzymatic hydrolysis pre-treatment methods can significantly improve the efficiency of the conversion process by breaking down complex components. The implementation of advanced monitoring and control systems can ensure optimal performance and reduce operating costs.

Integration of sensor technology and artificial intelligence can enable real-time process optimization.

Latest Research Findings in Dairy Waste Management

Recent research highlights promising advancements in dairy waste management. For instance, studies have demonstrated the effectiveness of combining anaerobic digestion with pyrolysis for enhanced energy recovery. Researchers have also explored the use of specific microbial consortia for improved methane production from complex dairy waste streams. The development of novel catalysts for biofuel production from dairy waste lipids is another area of active research.

These findings demonstrate a growing understanding of the intricate processes involved and point to potential for more efficient and sustainable solutions.

Futuristic Dairy Farm Implementing Waste-to-Energy Solutions

Imagine a modern dairy farm equipped with state-of-the-art waste-to-energy infrastructure. A large anaerobic digester, fed by a precisely controlled stream of dairy manure and whey, sits prominently on the farm. Sophisticated sensors monitor the process parameters in real-time, optimizing conditions for maximum biogas production. The generated biogas is then used to power a CHP system, providing electricity and heat for the farm operations, including milk processing and farm equipment.

The digestate, a nutrient-rich byproduct of the anaerobic digestion process, is used as fertilizer for the farm’s crops. The overall system minimizes environmental impact by reducing greenhouse gas emissions and maximizing resource utilization. A robust data management system tracks energy production, waste input, and resource utilization, allowing for continuous optimization of the process. The entire system is designed to be modular, allowing for expansion and integration with other renewable energy sources.

Final Thoughts

In conclusion, harnessing dairy waste as a renewable energy source presents a compelling opportunity for a more sustainable future in agriculture. By converting waste into valuable energy, we can reduce environmental pollution, create economic benefits, and promote responsible resource management within the dairy industry. The transition requires careful consideration of technical processes, economic viability, and environmental impact, but the potential rewards are substantial.