Dairy-Infused Brews A New Fusion

Combining the dairy industry with beer making opens exciting possibilities for innovative beverages. This exploration delves into the potential benefits, ingredient integration, product development, manufacturing considerations, market analysis, and the ethical and environmental aspects of this unique fusion.

Imagine creamy stouts, subtly sweet lagers, or even tangy sour ales – all crafted with the addition of dairy ingredients. This approach could revolutionize both industries, creating unique flavors and experiences for consumers.

Synergistic Potential

Brewing and dairy production, seemingly disparate industries, hold surprising potential for synergy. By combining these sectors, companies can unlock new market opportunities, create innovative products, and potentially enhance profitability. This exploration delves into the possibilities of blending these two worlds, from innovative product lines to enhanced economic advantages.Combining dairy and beer production offers a wealth of opportunities to create unique and desirable products.

The synergistic effect arises from the complementary nature of these ingredients, and the opportunity to leverage existing infrastructure and expertise in both industries. From the creamy texture of dairy to the complex flavors of beer, the potential for innovative combinations is vast.

Potential Benefits of Combining Dairy and Beer Production

Dairy products, with their diverse range of textures and flavors, can be used to enhance beer’s mouthfeel and complexity. Similarly, the subtle and robust flavors of beer can add depth to dairy-based products, creating a broader spectrum of culinary experiences. This approach could be particularly beneficial for developing new, specialized markets.

Examples of Successful Collaborations

While direct, documented collaborations between large dairy and brewery companies are relatively uncommon, there are examples of indirect synergies. For instance, a brewery might partner with a local dairy farm for sourcing high-quality milk or cream, which could lead to enhanced flavor profiles in their beers. Such partnerships can be mutually beneficial, providing the brewery with premium ingredients and the dairy farm with a new revenue stream.

Economic Advantages

The potential economic advantages are significant. Diversification of product lines for both industries can reduce dependence on traditional markets and enhance resilience against economic fluctuations. Furthermore, creating unique and appealing products can open doors to new customer segments, leading to increased revenue streams. For example, a dairy company producing specialized cheeses could partner with a brewery to create a line of craft beers paired with their cheese, thereby expanding their market reach.

Targeted Market Segments

The combined product lines can cater to a broad spectrum of consumers. Gourmet food enthusiasts, craft beer aficionados, and those seeking unique culinary experiences will be particularly interested in such offerings. This could be further expanded by developing seasonal or regional variations, further targeting niche segments. For example, a brewery producing a beer with local, seasonal milk could target local farmers’ markets and tourism hotspots.

Unique and Innovative Product Lines

The potential for developing unique and innovative product lines is immense. Imagine a stout beer infused with aged cheddar cheese, or a creamy porter enhanced with vanilla bean ice cream. Even a dairy-based sour beer, utilizing the lactic acid from cheese production, could offer a novel flavor experience. These unique combinations can position companies as leaders in the innovative food and beverage sector, creating a premium image and attracting discerning customers.

Potential Issues to Consider

While the potential is substantial, challenges exist. Manufacturing processes may require adaptation, and quality control standards need to be meticulously monitored. Careful planning and execution are essential to ensure successful integration of the two production lines. Moreover, regulatory considerations regarding labeling and ingredients need careful attention.

Ingredient Integration

Brewing with dairy isn’t just a novel idea; it’s a fascinating exploration of flavor possibilities. Integrating dairy ingredients into beer-making opens up a world of unexpected and intriguing flavor profiles. From subtle creaminess to bold, almost dessert-like notes, the possibilities are vast. The key is understanding how these ingredients interact with the existing beer components.

Dairy Ingredient Effects on Beer Characteristics

Dairy additions can significantly alter beer’s final character. Milk solids, whey proteins, and cream each impart unique qualities, affecting color, aroma, and mouthfeel. These modifications can lead to new and exciting styles of beer, pushing the boundaries of traditional brewing techniques.

| Dairy Ingredient | Effect on Beer Color | Effect on Beer Aroma | Effect on Beer Mouthfeel |

|---|---|---|---|

| Milk Solids | Slight increase in color, typically pale to medium amber. | Adds a creamy, slightly sweet aroma. May also impart a subtle caramel or toasted note depending on the specific milk type. | Increased body and mouthfeel, often leading to a velvety or smooth texture. |

| Whey Protein | Minimal impact on color. | Adds a subtly sweet and sometimes tangy aroma. May also contribute to a slightly acidic note. | Significant impact on body, creating a creamy or velvety texture. Often contributes to a substantial mouthfeel. |

| Cream | Slight increase in color, usually resulting in a lighter amber hue. | Adds a rich, creamy, and buttery aroma. May also incorporate subtle vanilla or caramel notes. | Substantial increase in body and mouthfeel, producing a luxurious, smooth texture. |

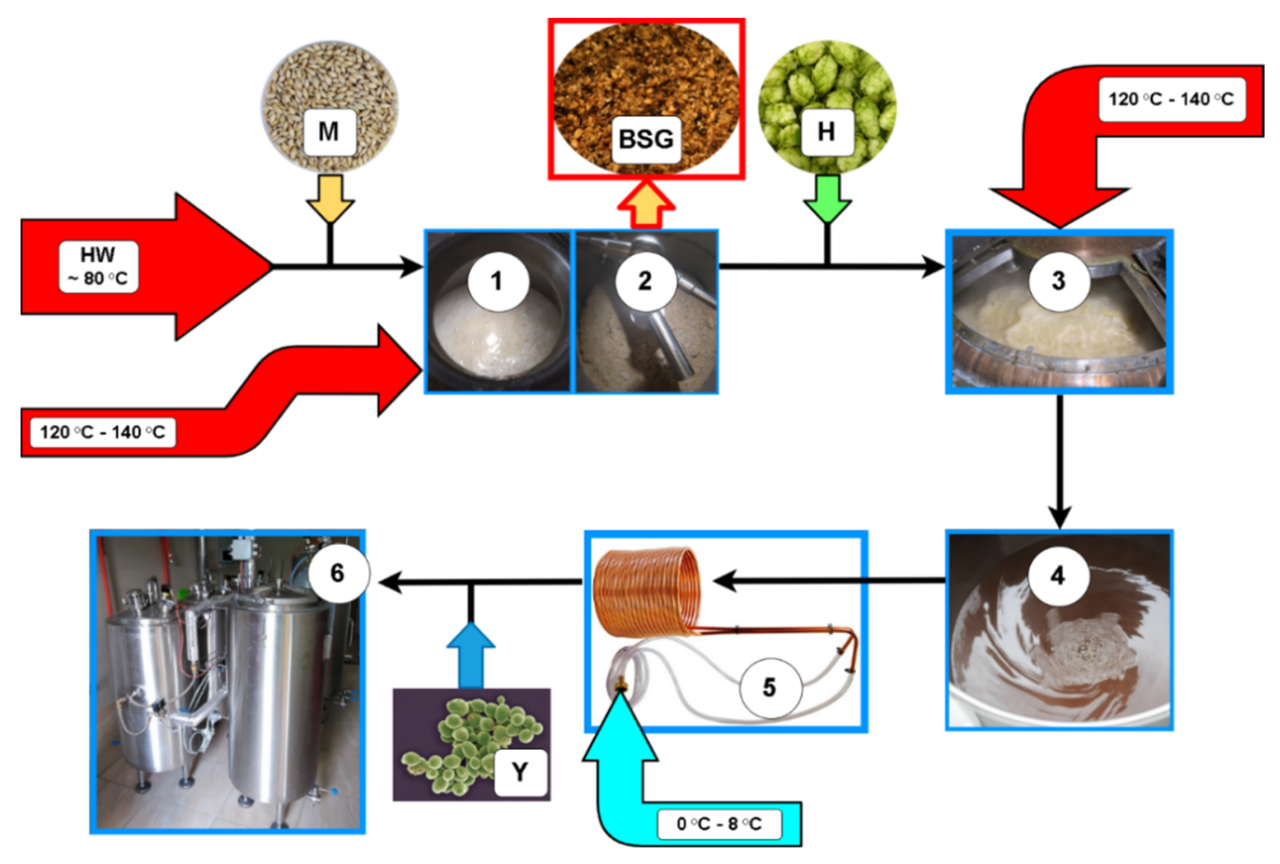

Methods for Incorporating Dairy Products

The methods for incorporating dairy products into brewing vary depending on the desired effect. Generally, dairy is added during the final stages of brewing, often after fermentation, to maintain consistency and flavor.

- Pre-fermentation additions: Dairy ingredients can be added to the wort before fermentation. However, this can potentially affect yeast activity and fermentation efficiency, which requires careful monitoring. It’s crucial to consider the specific characteristics of the yeast strain and the dairy ingredient’s impact on its activity.

- Post-fermentation additions: This method involves adding dairy after fermentation, allowing the beer’s primary characteristics to develop before introducing the dairy. This is generally considered a more effective method to preserve the beer’s original flavor while introducing dairy notes.

- Specific techniques: Using techniques like chilling the beer with the dairy ingredients added can enhance the creamy texture and prevent the milk from clumping. Precise temperature control throughout the process is crucial for maintaining consistency and preventing undesirable reactions.

Product Development: Combining The Dairy Industry With Beer Making

Brewing with dairy opens a world of possibilities, pushing the boundaries of traditional beer styles and creating unique sensory experiences. This exploration delves into the potential for novel beers by incorporating dairy ingredients, from the naming of the products to the sensory experience and specific brewing processes.The key is to understand how dairy components interact with the brewing process, influencing the final flavor profiles and mouthfeel.

This involves considering the specific dairy ingredients, their potential impact on the beer’s characteristics, and the desired outcome for the consumer experience.

Potential Product Names

This section presents imaginative names that evoke the unique combination of dairy and beer. These names are designed to pique consumer interest and highlight the distinctive character of these beverages.

- Creamy Porter

- Milky Stout

- Butterscotch Ale

- Honeyed Whey Wheat

- Goat’s Milk Gose

- Cheddar Pale Ale

- Yogurt Sour

Possible Flavors and Styles

The incorporation of dairy ingredients can lead to a diverse range of flavors and styles. Here are some potential options, leveraging the rich tapestry of dairy profiles:

- Creamy Stout: A rich, dark stout infused with milk solids, creating a velvety texture and a smooth, creamy mouthfeel. The sweetness of the milk solids complements the roastiness of the stout.

- Butterscotch Ale: A golden ale with a hint of butterscotch, achieved through the addition of butter or cream, resulting in a warm, comforting beverage.

- Honeyed Whey Wheat: A refreshing wheat beer infused with honey and whey, offering a balanced sweetness and a light, crisp finish. The whey adds a unique tangy element.

- Yogurt Sour: A sour ale featuring a subtle yogurt note, creating a tart and refreshing beer with a creamy mouthfeel. This style plays with the tangy and creamy aspects of yogurt.

- Goat’s Milk Gose: A traditional Gose with a distinct goat’s milk flavor, offering a unique tartness and a smooth texture. The goat’s milk lends a subtle complexity to the classic Gose.

Unique Branding Strategies

To capture the attention of consumers interested in this novel combination, a strong brand identity is crucial.

- Emphasize the uniqueness of the combination: Highlight the innovative blend of dairy and beer in the branding, showcasing the unexpected flavor profile.

- Showcase the quality of the dairy ingredients: Partner with artisanal dairy farms or producers to source high-quality ingredients, emphasizing the fresh, natural aspect in the branding.

- Create a visually appealing brand: Use imagery that evokes both the creamy texture of the dairy and the robust character of the beer, employing a modern, clean aesthetic.

- Tell a story: Develop a narrative around the unique brewing process and the collaboration between the breweries and dairy farms.

Sensory Experience

These beers offer a unique sensory experience, combining the robust flavors of beer with the smooth, creamy textures of dairy.

Thinking about combining the dairy industry with beer making? It’s a fascinating idea, and while exploring that, I stumbled upon some great news about the Stevens Points Breast Care Center receiving redesignation, which is excellent for the community. Stevens Points Breast Care Center receives redesignation highlights the importance of health initiatives. Ultimately, connecting the resources of the dairy industry to the brewing process could create some innovative, delicious, and potentially profitable new products, much like the improvements in the community health sector.

- Visual Appeal: The appearance will vary based on the specific style, ranging from the dark brown hues of stouts to the golden tones of ales. The addition of milk solids might create a subtle cloudiness.

- Aroma: The aroma will capture a range of notes, from the roasted malt of a stout to the sweet, buttery nuances of a butterscotch ale.

- Taste: The taste will deliver a balanced interplay between the beer’s characteristics and the dairy’s subtle notes, with the creamy mouthfeel enhancing the overall experience.

- Mouthfeel: The dairy ingredients will impart a velvety, creamy texture, complementing the carbonation and bitterness of the beer.

Ingredient, Process, and Taste Profile Table

| Beer Type | Dairy Ingredient | Brewing Process | Expected Taste Profile |

|---|---|---|---|

| Cream Stout | Milk Solids | Milk solids added during the mash or boil, with careful temperature control to avoid curdling. | Rich, dark, roasty flavors of stout, with a smooth, creamy texture and a slightly sweet note from the milk solids. |

| Butterscotch Ale | Butter | Butter added during the boil or in the fermentation process. | Malty, slightly sweet ale with a rich, butterscotch-like flavor from the butter. |

| Honeyed Whey Wheat | Whey, Honey | Whey added during the boil, Honey added during fermentation. | Crisp, refreshing wheat beer with a slight tang from the whey and a subtle sweetness from the honey. |

| Yogurt Sour | Yogurt Culture | Yogurt culture added during the fermentation process. | Tart, refreshing sour ale with a subtle yogurt flavor and a creamy mouthfeel. |

Manufacturing Considerations

Brewing with dairy presents unique challenges and opportunities. Integrating these ingredients into the established brewery workflow requires careful consideration of the entire process, from ingredient handling to quality control. Understanding the specific impacts on fermentation, equipment modifications, and sanitation protocols is crucial for successful production.Integrating dairy into the beer-making process demands a proactive approach to manufacturing. The delicate nature of dairy products, coupled with the specific needs of beer production, necessitates meticulous attention to detail at every stage.

This involves not only understanding the chemical interactions between dairy components and the beer, but also adapting the brewery’s existing infrastructure to accommodate these new ingredients.

Challenges Associated with Dairy Integration

The introduction of dairy into beer production presents several challenges. Dairy products, particularly milk, are susceptible to contamination, requiring rigorous sanitation and hygiene protocols. Maintaining consistent quality across batches is paramount, demanding precise measurement and control of ingredient quantities and temperatures. The impact on fermentation kinetics and final product characteristics also needs to be carefully assessed. Furthermore, the potential for unwanted flavors and textures in the beer must be minimized.

All of these factors contribute to the complex nature of dairy integration in the brewing process.

Impact of Dairy on Fermentation Processes

The addition of dairy proteins and fats can influence fermentation dynamics. Lactose, a sugar present in milk, can be consumed by yeast, potentially affecting fermentation rates and final alcohol content. Casein and whey proteins can impact the colloidal stability of the beer, potentially leading to haze formation. Furthermore, the presence of milk fats can influence the texture and mouthfeel of the beer, introducing an entirely new dimension to the final product.

The specific strains of yeast used, as well as the fermentation temperature, will significantly influence the impact of dairy on the fermentation process.

Equipment Modifications for Dairy Integration

Brewing facilities require adjustments to accommodate dairy ingredients. Dedicated storage and handling equipment for milk and dairy products are essential. Temperature-controlled storage systems for milk and other dairy products are needed to maintain optimal quality. Specialized pipelines and pumps capable of handling dairy products without cross-contamination with other ingredients are necessary. Furthermore, filtration systems may need modification to remove any potential particulates or clumps from the dairy products.

These changes should adhere to stringent hygienic standards to prevent contamination and ensure consistent product quality.

Quality Control Measures for Consistent Product Quality

Maintaining consistent product quality is vital when incorporating dairy ingredients. Precise ingredient measurements and standardized processing protocols are critical. Regular monitoring of fermentation parameters, such as temperature, pH, and dissolved oxygen, is necessary. Sensory evaluation of the final product, including taste, aroma, and mouthfeel, is important to ensure the desired outcome. Comprehensive record-keeping of all processing steps, ingredient quantities, and environmental conditions is essential for quality control.

This data allows for the identification of any deviations and enables adjustments to the process for improved consistency.

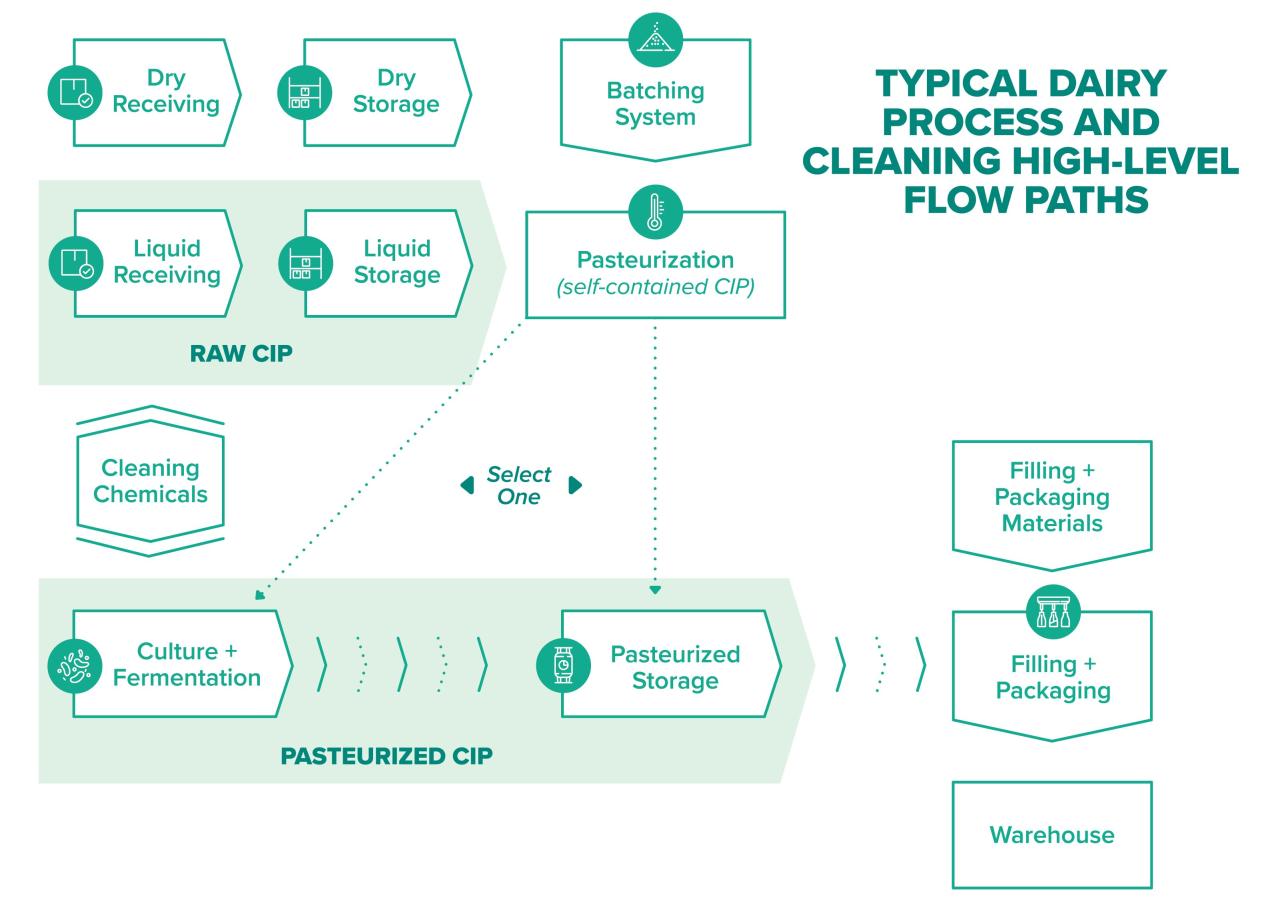

Sanitation and Hygiene Protocols for Dairy Handling

Strict sanitation and hygiene protocols are paramount when handling dairy products in a brewery. Dairy products are highly susceptible to contamination, demanding rigorous cleaning and sanitization procedures for all equipment and surfaces. The use of dedicated equipment for dairy handling is highly recommended to prevent cross-contamination with other ingredients. The implementation of robust cleaning-in-place (CIP) systems for dairy equipment is essential to maintain a sterile environment.

Regular staff training on proper hygiene and sanitation practices is vital to maintain a high level of safety and quality.

Market Analysis

The dairy and beer industries, while seemingly disparate, both possess robust and evolving markets. Understanding current trends and potential consumer preferences is crucial for navigating the complexities of a new product category. This analysis will examine current market trends, potential consumer preferences, competitive landscape, target audience, and pricing strategies for dairy-infused beers.Analyzing the market for dairy-infused beers necessitates a thorough understanding of existing market trends within both the dairy and beer industries.

This insight provides a framework for evaluating the potential of this novel product.

Thinking outside the milk carton? Combining the dairy industry with beer making could be a fantastic new venture, especially with the recent news about Oshkosh eyes new development near the Fox River. oshkosh eyes new development near fox river. This could create a unique synergy, potentially leveraging the area’s resources for a thriving local brewery using local dairy products.

Imagine the possibilities for innovative, flavourful brews! The dairy industry is ripe for exciting collaborations.

Current Market Trends in Dairy and Beer, Combining the dairy industry with beer making

The dairy industry is experiencing a shift toward healthier, functional foods and beverages, with an emphasis on natural and organic products. Consumers are increasingly seeking dairy alternatives, such as plant-based milk options, but traditional dairy still holds a significant market share. In the beer industry, craft beer continues to gain popularity, driven by a demand for diverse flavors and unique experiences.

This trend is coupled with an ongoing exploration of new flavor profiles and brewing techniques. These trends indicate a willingness from consumers to explore novel combinations.

Potential Consumer Preferences for Dairy-Infused Beers

Consumers are showing a growing interest in innovative and unique flavor combinations. Dairy-infused beers offer a potential avenue for appealing to this segment, particularly those who enjoy both dairy products and craft beers. The creamy texture and subtle sweetness of dairy components can complement the bitterness and hop characteristics of beer. Furthermore, dairy can contribute to a smoother, more complex mouthfeel.

Taste testing and consumer surveys will be crucial to determine the specific flavor profiles most appealing to the target audience.

Competitive Analysis and Market Share

The current beer market is highly competitive, with established brands and a vast array of craft breweries. Dairy-infused beers will need to carve out a niche within this existing landscape. While quantifying the exact market share for this new category is difficult, success will likely depend on factors such as brand recognition, unique flavor profiles, and marketing strategies.

A strategic focus on highlighting the distinct qualities of the dairy-infused beer is key to achieving a significant market share. Existing successful craft beers can serve as models for effective branding and marketing campaigns.

Ever thought about combining the dairy industry with beer making? It’s a fascinating idea, and the potential for innovation is huge. Finding ways to use byproducts from dairy farms, like whey, in beer production could be a game-changer for both industries. This innovative approach could also help with sustainability efforts, like those being championed by sustaining our waters the fox wolf watershed alliance.

Ultimately, creating a more sustainable system where dairy and beer production can coexist is a win-win, offering exciting possibilities for the future of both sectors.

Target Audience

The ideal target audience for dairy-infused beers is likely to be craft beer enthusiasts who are also open to exploring new and unique flavor combinations. This demographic is likely to appreciate the balance between the familiar and the innovative. They are frequently interested in locally sourced ingredients, and often prioritize the experience of trying new products. Consumers interested in unique, flavorful, and premium beverages also fall into this category.

The target audience should be further segmented based on detailed market research.

Pricing Strategies

Pricing strategies will need to consider the cost of ingredients, production, and marketing. Premium dairy-infused beers could be priced at a slight premium to traditional craft beers, reflecting the unique nature of the product and the higher quality ingredients used. Competitive pricing models are also necessary to maintain competitiveness. The final price will need to reflect the value proposition of the product, aligning with consumer expectations.

This strategy must also account for the price elasticity of demand, a crucial factor in the overall success of the product. Analysis of the price points of similar products in the craft beer market is important to establish a profitable pricing strategy.

Sustainability and Ethical Considerations

Brewing beer with dairy presents a fascinating opportunity, but also a crucial need for mindful consideration of its environmental and ethical impacts. Integrating dairy into beer production necessitates a thorough evaluation of the entire supply chain, from farm to bottle, to ensure responsible and sustainable practices are adopted throughout. This meticulous approach will be vital for the long-term success and positive reputation of this innovative brewing method.The potential benefits of dairy-infused beers are undeniable, but careful consideration of the environmental impact and ethical sourcing is essential.

The dairy industry already faces scrutiny regarding its environmental footprint, and this trend adds another layer to the discussion. This necessitates a proactive approach to minimizing negative consequences and ensuring the entire process remains environmentally sound.

Environmental Impact of Dairy in Beer Production

The environmental impact of dairy in beer production stems from various stages, encompassing feed production, livestock farming, processing, and transportation. A significant factor is the carbon footprint associated with dairy production. The production of dairy feed, particularly if it relies heavily on land conversion and intensive farming practices, contributes significantly to greenhouse gas emissions. Furthermore, transportation of dairy ingredients from farm to brewery adds to the overall carbon footprint.

The manufacturing process itself can also generate waste and energy consumption.

Ethical Sourcing of Dairy Ingredients

Ensuring ethical sourcing is paramount. Dairy farmers practicing sustainable farming methods, such as rotational grazing, reduced antibiotic use, and responsible waste management, are crucial to a positive impact. Traceability of the dairy ingredients is essential to verify that they come from farms adhering to ethical standards. Transparency in the supply chain helps consumers make informed decisions and ensures that the entire process reflects a commitment to ethical practices.

Potential Impact on the Dairy Industry

The integration of dairy into the beer industry presents a unique opportunity for the dairy industry to diversify its market and potentially boost demand for certain dairy products. This could lead to increased demand for specialty dairy products, driving innovation and potentially higher profitability. However, it also necessitates careful planning to avoid price fluctuations or supply chain disruptions. The dairy industry must adapt and respond to the emerging demand, while simultaneously upholding its commitment to sustainability.

Strategies for Minimizing the Environmental Footprint

Several strategies can minimize the environmental footprint of this process. Implementing carbon-neutral transportation strategies, using renewable energy sources during processing, and optimizing waste management systems are crucial steps. Investing in research and development of more sustainable dairy farming practices, like precision agriculture, is vital. Employing innovative techniques like closed-loop systems for waste recycling and reducing water consumption in dairy processing can significantly minimize the environmental footprint.

Examples of Environmentally Friendly and Sustainable Dairy Farming Practices

- Rotational Grazing: This technique involves moving livestock between different pastures, allowing for natural regeneration of grasses and reducing soil erosion.

- Reduced Antibiotic Use: Prioritizing preventative health measures and promoting healthy animal husbandry reduces the need for antibiotics, improving animal welfare and reducing antibiotic resistance.

- Improved Feed Efficiency: Optimizing feed rations and using high-quality feed ingredients can improve animal health and reduce the environmental impact of feed production.

- Manure Management: Proper manure management practices can transform manure into valuable fertilizer, reducing the need for synthetic fertilizers and minimizing pollution.

Implementing these practices can significantly reduce the environmental impact of dairy farming, making it a more sustainable and responsible sector. Furthermore, farmers can be incentivized through governmental support, subsidies, and educational programs to adopt these methods.

Final Conclusion

The potential for combining dairy and beer is vast, promising exciting new avenues for product development and market expansion. From the integration of dairy ingredients to the design of innovative branding strategies, this fusion holds the key to creating a compelling new category of beverages. However, careful consideration of manufacturing challenges, market analysis, and ethical sourcing is crucial for long-term success.