Delivering Critical Infrastructure Materials Across the US

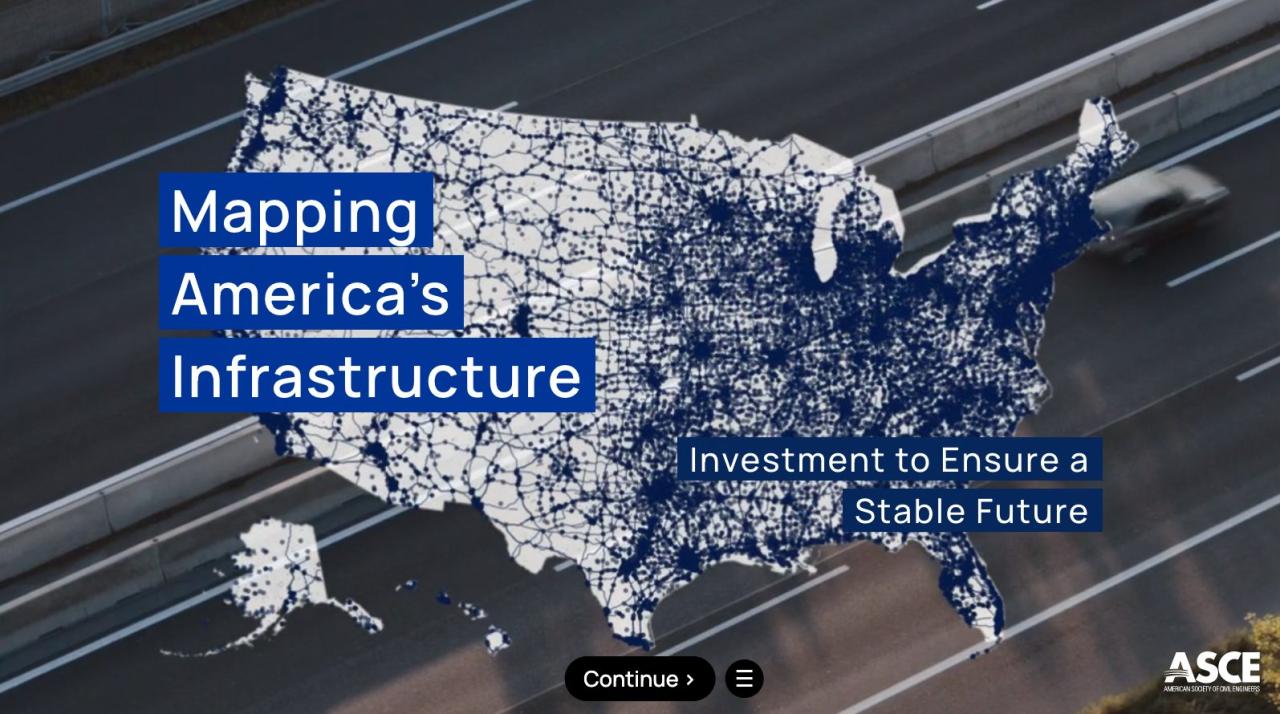

Delivering critical infrastructure materials throughout the u s – Delivering critical infrastructure materials throughout the U.S. is a complex logistical undertaking, impacting everything from vital transportation networks to energy grids. This process demands meticulous planning, efficient transportation methods, and a deep understanding of the unique challenges presented by diverse geographical regions and varying project requirements.

From the intricate choreography of trucking, rail, and maritime transport to the careful handling and storage of materials like steel and concrete, this article explores the multifaceted aspects of delivering these essential components for critical infrastructure projects across the country. We’ll delve into the advantages and disadvantages of each mode of transport, the role of technology in streamlining processes, and the vital importance of safety protocols and regulations.

Logistics and Transportation

The seamless delivery of critical infrastructure materials across the US hinges on a robust and adaptable logistics network. Efficient transportation strategies are crucial for minimizing delays, ensuring timely project completion, and ultimately, maintaining the integrity and functionality of our nation’s infrastructure. This includes not just the physical movement of materials but also the intricate coordination between various stakeholders, from suppliers to construction crews.The choice of transportation mode significantly impacts the cost, speed, and feasibility of delivering specific materials.

Understanding the nuances of each method is paramount for optimized supply chain management.

Transportation Modes for Critical Infrastructure Materials, Delivering critical infrastructure materials throughout the u s

Various transportation modes are employed for delivering critical infrastructure materials throughout the US. Each mode possesses unique advantages and disadvantages, making the selection dependent on the characteristics of the materials, the destination, and the overall project timeline.

- Trucking: Trucking remains the most prevalent mode for short-to-medium distances, especially for smaller loads and materials requiring flexibility in route adjustments. Its agility and accessibility to various locations are key strengths. However, trucking can be slower and more costly than rail or water transport for long-distance shipments.

- Rail: Rail transport excels in handling large volumes of materials over extended distances. Its cost-effectiveness for bulk shipments makes it ideal for transporting raw materials like steel and concrete aggregates. However, rail’s fixed routes and slower speeds can hinder the responsiveness needed for urgent deliveries.

- Air: Air transport is typically reserved for urgent or time-sensitive deliveries of specialized equipment or components. Its speed is unparalleled, making it valuable for critical infrastructure projects demanding rapid deployment. However, the high cost and limited capacity restrict its widespread use for large-scale material transport.

- Water: Water transport is a cost-effective option for bulk shipments of materials over long distances, especially for heavy, non-perishable goods like concrete and asphalt. Large quantities of materials can be transported simultaneously, minimizing individual shipment costs. However, its reliance on water routes and weather conditions can cause delays.

Comparative Analysis of Transportation Modes

A comparison of transportation modes reveals their varying strengths and weaknesses.

| Transportation Mode | Cost | Speed | Capacity | Suitability |

|---|---|---|---|---|

| Trucking | Moderate | Moderate | Variable | Short-medium distances, flexible routes |

| Rail | Low | Slow | High | Long distances, bulk materials |

| Air | High | Fast | Low | Urgent deliveries, specialized components |

| Water | Low | Slow | High | Long distances, bulk materials |

Typical Routes and Timelines for Critical Infrastructure Materials

The specific routes and timelines for transporting critical infrastructure materials vary greatly depending on the region, material type, and the overall project schedule.

- Region-specific considerations: Transportation routes in the West Coast, for example, may involve a combination of rail and trucking, while the South might rely more heavily on truck transport. Factors like road conditions, weather patterns, and seasonal fluctuations need careful consideration in the planning stage.

- Material type impact: The route and timeline for transporting concrete precast panels will differ from the route for transporting specialized steel components for a bridge. This is due to the varied nature of the materials themselves and the requirements for their safe transport.

Successful Supply Chain Management Strategies

Successful supply chain management for critical infrastructure materials involves meticulous planning and coordination. Several strategies have proven effective in achieving timely delivery.

- Proactive planning: Forecasting material needs well in advance allows for the allocation of resources and the securing of necessary transportation capacity. This prevents bottlenecks and delays.

- Robust communication: Clear communication channels between suppliers, contractors, and transportation providers are vital for seamless coordination and timely updates. This reduces uncertainty and promotes transparency.

- Flexible contingency plans: The development of alternative routes or transportation modes in case of unforeseen events (like severe weather) is essential. This ensures minimal disruption to project timelines.

Material Handling and Storage: Delivering Critical Infrastructure Materials Throughout The U S

Getting critical infrastructure materials to the right place at the right time requires meticulous planning and execution. This involves more than just transportation; it necessitates robust material handling and storage strategies. Effective management of these aspects ensures project efficiency, safety, and timely completion. This is crucial, especially in high-stakes projects involving critical infrastructure, where delays can have significant consequences.Proper material handling and storage are paramount to the successful delivery of critical infrastructure projects.

This encompasses a comprehensive approach, from the initial receiving and sorting of materials to their secure and organized storage at various project locations. These procedures, when followed meticulously, can significantly reduce project delays and ensure the integrity of the materials, ultimately contributing to the overall success of the project.

Material Handling Methods

Different materials require different handling methods. For instance, heavy machinery components necessitate specialized lifting equipment, whereas prefabricated sections of buildings might be transported using cranes or specialized trailers. The specific method depends on the size, weight, and fragility of the material. Safe handling practices, including proper lifting techniques and the use of appropriate safety gear, are essential.

Storage Protocols and Safety Procedures

Strict safety protocols are critical for handling and storing these materials. This includes training personnel on proper lifting techniques, using appropriate personal protective equipment (PPE), and adhering to established procedures for handling hazardous materials. Implementing robust safety procedures minimizes accidents and protects workers. Regular inspections of storage facilities and equipment are vital to ensure structural integrity and adherence to safety standards.

Types of Storage Facilities

The choice of storage facility depends on the nature of the materials being stored. Different materials require different environments to maintain their quality and prevent degradation. This involves considering factors such as temperature, humidity, and security.

| Material Type | Storage Facility Type | Security Measures |

|---|---|---|

| Steel beams | Covered outdoor storage yard with designated areas | Security fencing, perimeter lighting, CCTV surveillance, regular patrols |

| Pre-fabricated building sections | Climate-controlled warehouse with racking systems | Access control, security personnel, regular inventory checks, fire suppression systems |

| Electrical components | Specialized climate-controlled warehouse with ESD (electrostatic discharge) protection | Access control, security personnel, regular inventory checks, humidity control systems |

| Hazardous materials (e.g., chemicals) | Designated hazardous material storage facility with strict protocols | Security fencing, double-locked storage containers, specialized personnel training, emergency response plan |

Efficient Material Handling and Storage

Efficient material handling and storage significantly impact project timelines. Well-organized storage minimizes the time spent locating materials, reducing delays in construction or installation phases. Streamlined processes for receiving, storing, and retrieving materials translate directly to faster project completion. For instance, a project using a dedicated inventory management system can significantly reduce material handling time and minimize errors, thus reducing the overall project duration.

Effective material management, in conjunction with accurate scheduling, contributes to achieving project milestones on time and within budget.

Infrastructure Types and Materials

The United States boasts a vast and complex infrastructure network, critical for its economic vitality and societal well-being. From the highways that crisscross the nation to the power plants that fuel our homes, maintaining and expanding these systems requires careful consideration of material selection and logistical execution. This section dives into the types of critical infrastructure projects and the materials underpinning them.Understanding the characteristics and properties of these materials is essential for ensuring durability, efficiency, and safety.

This knowledge, coupled with effective procurement and delivery strategies, is crucial for maintaining and expanding the country’s infrastructure.

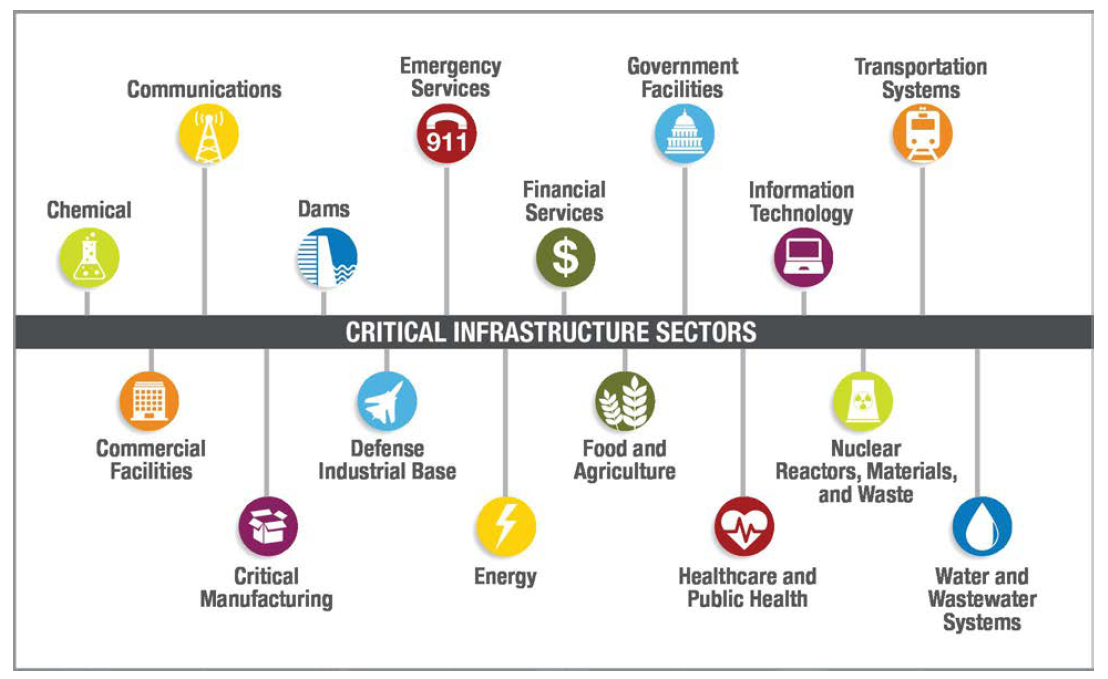

Key Types of Critical Infrastructure Projects

The United States’ critical infrastructure encompasses a wide array of projects, each with unique requirements. These include, but are not limited to, bridges, roads, power plants, water systems, and communication networks. These projects form the backbone of the nation’s economy and daily life, ensuring reliable transportation, energy supply, and essential services.

Material Properties and Characteristics

The materials used in critical infrastructure projects exhibit specific properties crucial for their functionality and longevity. Steel, for instance, is renowned for its high tensile strength, making it ideal for bridges and structural components. Concrete, a composite material, provides compressive strength and durability, often used in foundations and pavements. Asphalt, a bituminous mixture, excels in road construction, providing a resilient surface capable of withstanding traffic and environmental stresses.

Each material’s unique properties determine its suitability for particular infrastructure applications.

Challenges in Procurement and Delivery

Procuring and delivering specialized materials for diverse infrastructure projects across the vast geographic landscape of the US presents considerable challenges. Variations in climate, terrain, and local regulations significantly impact the logistical planning and execution of these projects. Ensuring timely delivery of materials to construction sites while maintaining quality control is paramount for project success. Furthermore, fluctuating material costs and supply chain disruptions can further complicate the process.

Material Requirements for Infrastructure Projects

The table below illustrates the typical material requirements for different infrastructure projects. The precise quantities will vary based on the specific project scope and design specifications.

| Infrastructure Project | Primary Materials | Secondary Materials | Quantity Considerations |

|---|---|---|---|

| Bridge Construction | Steel, concrete | Bolts, rivets, reinforcing bars | Dependent on span length, traffic load, and design specifications |

| Highway Construction | Asphalt, concrete | Aggregates, binders, marking materials | Dependent on road type, traffic volume, and environmental conditions |

| Power Plant Construction | Steel, concrete, copper | Insulation materials, piping | Dependent on plant capacity, fuel type, and safety standards |

| Water System Construction | Concrete, steel, plastic pipes | Valves, fittings, and sensors | Dependent on water flow requirements and geographic conditions |

Challenges and Solutions

Delivering critical infrastructure materials across the US presents a complex web of challenges. From navigating unpredictable weather patterns to managing labor shortages and supply chain disruptions, the process demands robust planning and adaptable strategies. Addressing these obstacles is crucial for ensuring timely and secure material delivery, ultimately safeguarding the integrity and functionality of our nation’s infrastructure.Successfully navigating the logistics of critical infrastructure material delivery requires a multifaceted approach.

Effective solutions not only address immediate problems but also build resilience against future disruptions. This involves a thorough understanding of potential risks, proactive mitigation strategies, and the implementation of robust contingency plans.

Weather-Related Challenges

Unpredictable weather conditions significantly impact transportation schedules and the integrity of infrastructure materials. Heavy snowfall, extreme temperatures, and severe storms can disrupt transportation networks, leading to road closures, flight cancellations, and material damage. This necessitates proactive measures to assess and account for these risks. For example, winter storms often cause significant delays in the delivery of crucial materials for road repairs, impacting the safety and efficiency of the transportation system.

A thorough analysis of historical weather patterns and the identification of vulnerable routes are critical in mitigating these risks.

Road Closures and Infrastructure Limitations

Road closures due to accidents, maintenance, or natural disasters can severely disrupt the flow of materials. Furthermore, inadequate infrastructure, including poorly maintained roads or bridges, can pose challenges to transportation. Implementing alternative routes, pre-approved detour plans, and prioritizing critical deliveries can help manage such disruptions.

Labor Shortages and Staffing Constraints

Labor shortages, particularly in transportation and logistics, can lead to delays in material handling and delivery. This requires proactive strategies to ensure adequate staffing levels. This could involve partnerships with local transportation companies or exploring the use of automation and technology to optimize delivery processes. For instance, increased automation in material handling at distribution centers could significantly reduce the reliance on manual labor and mitigate delays caused by staffing issues.

Delivering critical infrastructure materials throughout the US is a complex logistical challenge. It’s about more than just getting things from point A to point B; it’s about ensuring timely delivery to keep projects on schedule and within budget. This often involves navigating various regulations and partnerships, such as exploring innovative approaches like those highlighted in the ‘Hello world!’ article, Hello world! Ultimately, smooth and efficient delivery of these materials is vital for the ongoing construction and maintenance of essential services across the country.

Supply Chain Disruptions and Contingency Planning

Supply chain disruptions, whether caused by global events, natural disasters, or unforeseen circumstances, can lead to significant delays in material deliveries. Developing robust contingency plans and diversifying supply sources are crucial for minimizing the impact of disruptions. A crucial component of contingency planning involves identifying backup suppliers, alternative routes, and the establishment of emergency response teams to manage unexpected situations.

Risk Assessment and Mitigation Strategies

A thorough risk assessment is fundamental to ensuring timely and secure delivery of critical infrastructure materials. This involves identifying potential risks, analyzing their likelihood and impact, and developing mitigation strategies to minimize the negative consequences. Developing a comprehensive risk assessment process will enable stakeholders to prioritize resources and address potential challenges effectively.

Comparison of Supply Chain Disruption Management Strategies

Various strategies can be employed to manage supply chain disruptions. One approach is to enhance supplier diversity, ensuring multiple sources for critical materials. Another strategy involves implementing real-time tracking systems and communication channels to maintain transparency and control over the delivery process. The adoption of advanced analytics and predictive modeling can help identify potential disruptions in advance, allowing for proactive mitigation strategies.

Security and Regulations

Protecting critical infrastructure materials is paramount. Robust security measures are essential throughout the entire supply chain, from initial production to final installation. These materials are often targets for theft or malicious intent, so safeguards are crucial to ensure their integrity and prevent disruption of essential services. Regulations and compliance requirements play a vital role in ensuring the safe and secure handling of these materials.Comprehensive security protocols are implemented to deter unauthorized access and protect these materials from harm.

These protocols are often tailored to the specific characteristics of the materials being transported and stored, considering factors such as their value, fragility, and potential for misuse. Furthermore, strict adherence to regulations is vital for maintaining compliance, safeguarding personnel, and avoiding costly penalties.

Security Measures for Transportation and Storage

Security measures are multifaceted and involve a range of approaches. Physical security measures, such as controlled access points, perimeter fencing, and surveillance systems, are implemented to prevent unauthorized individuals from gaining access to storage facilities and transportation vehicles. Advanced technologies like biometric identification and access control systems are also employed. Transportation security involves the use of secure vehicles, advanced tracking systems, and armed escorts for high-value shipments.

Regular security audits and risk assessments are crucial to identify vulnerabilities and adapt security protocols accordingly.

Regulatory Compliance Requirements

Adherence to relevant regulations is critical. Compliance with regulations ensures that materials are handled safely and securely, minimizing the risk of accidents or incidents. This includes adherence to environmental regulations for waste disposal and pollution control. Specific regulations concerning hazardous materials transportation and storage are also in place to prevent harm to personnel and the environment. International agreements and treaties may also apply depending on the materials and their origin or destination.

Importance of Safety Protocols and Procedures

Safety protocols and procedures are indispensable. Properly trained personnel are critical for safe material handling, storage, and transportation. Emergency response plans are also vital in case of accidents or incidents. Regular safety training sessions for all personnel involved in the supply chain are crucial to maintain a high level of safety awareness.

Security Protocols and Regulatory Compliance Measures

| Category | Protocol/Measure | Description |

|---|---|---|

| Physical Security | Controlled Access Points | Restricting access to designated areas using security personnel, keycards, or biometric systems. |

| Physical Security | Perimeter Fencing | Enclosing storage facilities and transportation routes with secure fencing and alarm systems. |

| Physical Security | Surveillance Systems | Employing CCTV cameras and other surveillance technologies to monitor activities within facilities and during transit. |

| Transportation Security | Secure Vehicles | Utilizing vehicles designed to withstand potential attacks and equipped with security features. |

| Transportation Security | Advanced Tracking Systems | Implementing GPS tracking and real-time monitoring of shipments for enhanced security and accountability. |

| Transportation Security | Armed Escorts | Providing armed security personnel for high-value or sensitive shipments to deter theft and ensure protection. |

| Regulatory Compliance | Hazardous Materials Regulations | Adhering to strict regulations governing the transportation, storage, and handling of hazardous materials. |

| Regulatory Compliance | Environmental Regulations | Complying with environmental standards for waste disposal, pollution control, and resource management. |

| Safety Protocols | Regular Safety Training | Providing comprehensive training to personnel on safety procedures, emergency response, and hazard identification. |

| Safety Protocols | Emergency Response Plans | Developing and regularly testing emergency plans for accidents, incidents, and potential threats. |

Technological Advancements

The delivery of critical infrastructure materials hinges on innovative technologies to ensure efficiency, security, and reliability. From the initial sourcing to final installation, technology plays a crucial role in streamlining processes and mitigating risks. This section delves into the transformative power of technology in modern supply chain management for these vital materials.Technology is not just a supporting element; it’s integral to the modern delivery process of critical infrastructure materials.

The sheer volume, complexity, and importance of these materials necessitate a robust and adaptable technological framework to manage the entire supply chain effectively.

GPS Tracking and Real-Time Monitoring

Real-time GPS tracking systems provide invaluable insights into the movement of materials. This technology allows for constant monitoring of vehicle locations, speeds, and adherence to schedules. This continuous tracking enables proactive identification and resolution of potential delays, enhancing the overall efficiency of the delivery process. Furthermore, it enables better route optimization and reduces fuel consumption. The data collected from these systems can be used to create detailed maps and charts illustrating the movement of materials, enhancing visibility for stakeholders.

Predictive Analytics for Supply Chain Optimization

Predictive analytics tools leverage historical data and current trends to anticipate potential disruptions and challenges in the supply chain. By identifying potential bottlenecks, delays, and material shortages in advance, these tools allow for proactive adjustments and mitigation strategies. For instance, a predictive model can identify a looming shortage of a specific steel grade, allowing for alternative sourcing or expedited ordering, thereby avoiding delays in critical infrastructure projects.

This advanced forecasting capability is crucial for maintaining the continuity and timely completion of projects.

Material Condition Monitoring

Technological advancements in sensors and data transmission allow for continuous monitoring of material conditions during transit. Sensors can track factors such as temperature, humidity, and vibration, alerting personnel to potential damage or degradation of the materials. Real-time alerts regarding these conditions provide crucial information for mitigating risks and ensuring the integrity of the materials throughout the delivery process.

For example, temperature-sensitive components can be tracked in real-time to maintain their optimal conditions.

Data Analysis for Route Optimization and Delay Reduction

Data analysis plays a pivotal role in optimizing delivery routes and reducing delays. Sophisticated algorithms can analyze factors like traffic patterns, road closures, and weather conditions to identify the most efficient routes. Furthermore, these algorithms can predict potential delays and suggest alternative routes to maintain schedule adherence. This optimization can translate into significant cost savings and reduced environmental impact by minimizing fuel consumption and maximizing efficiency.

For example, a logistics company might use data analysis to discover that using a specific route during peak hours consistently results in significant delays, prompting them to alter their delivery schedules accordingly.

Impact on Local Communities

Delivering critical infrastructure materials across the US has a significant ripple effect on local communities. This impact isn’t just about the construction itself; it encompasses a wide range of potential benefits and drawbacks, from job creation to traffic disruptions and environmental consequences. Understanding these impacts is crucial for responsible planning and effective mitigation strategies.The delivery of materials for critical infrastructure projects, such as highways, bridges, and power grids, can bring considerable economic benefits to local communities.

This process often generates employment opportunities in construction, transportation, and related industries. However, these benefits can be offset by negative impacts like increased traffic congestion, noise pollution, and potential environmental damage.

Positive Impacts

The influx of construction materials can stimulate local economies by creating jobs and increasing demand for goods and services. For instance, companies involved in material handling, transportation, and related businesses experience growth, leading to higher employment rates and increased local tax revenue. Moreover, the construction process itself can lead to an increase in local business activity, boosting the overall economic well-being of the community.

Negative Impacts

Increased traffic congestion, particularly during peak delivery hours, can disrupt daily life and negatively affect residents’ commutes. Construction activities can also produce noise pollution, dust, and other environmental hazards. These issues are especially important to address, as they can have long-term consequences for residents’ quality of life. For example, the construction of a major highway in a residential area could lead to long-term disruptions to daily life and increased stress for residents.

Mitigation Strategies

Effective mitigation strategies are crucial to minimize the negative impacts of infrastructure material delivery. These strategies include:

- Implementing optimized delivery schedules to reduce traffic congestion and disruption during peak hours.

- Utilizing alternative transportation methods, such as rail or water transport, where feasible, to lessen the impact on roadways.

- Employing noise barriers and dust control measures during construction to reduce the impact on residents.

- Implementing robust environmental impact assessments and adherence to environmental regulations to minimize the potential for long-term environmental damage.

These measures can significantly reduce the negative impacts of infrastructure material delivery, promoting a more harmonious relationship between construction activities and local communities.

Community Engagement and Communication

Open communication and community engagement are essential for a successful infrastructure project. This process involves proactively informing residents about project timelines, potential impacts, and mitigation strategies. Holding public meetings, town halls, and online forums is a crucial step in ensuring transparency and building trust between the project team and the community.

Examples of Community Outreach Programs

Community outreach programs can effectively involve local residents in the infrastructure planning process. Examples include:

- Public meetings and forums: Hosting meetings to discuss the project’s potential impacts and solicit feedback from community members.

- Interactive website or app: Providing an online platform for community members to access project information, ask questions, and share concerns.

- Community advisory boards: Establishing a panel of community representatives to provide input on project design and implementation.

- Targeted communication campaigns: Distributing information about the project through local media outlets, community newsletters, and direct mail.

These initiatives can foster trust and understanding, ensuring that infrastructure projects are implemented in a way that benefits both the community and the project itself.

Closure

In conclusion, the seamless delivery of critical infrastructure materials across the U.S. hinges on a sophisticated interplay of logistics, material handling, and a proactive approach to challenges. Successfully navigating these complexities requires a robust understanding of the diverse needs of various projects, the meticulous adherence to safety protocols, and the proactive implementation of technological advancements. The interconnectedness of these elements is crucial for timely and secure delivery, ultimately supporting the nation’s infrastructure development and resilience.