La Crosse Distilling Co Full Circle Sustainability

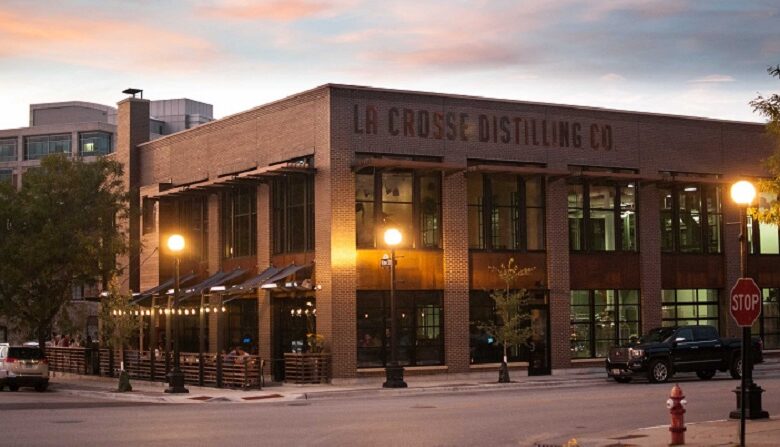

La Crosse Distilling Co focuses on full circle sustainability, a holistic approach to environmental responsibility. This involves everything from sourcing raw materials ethically to minimizing waste and engaging with the local community. They aim to create a truly circular system where every element of their operation contributes to a more sustainable future.

The company meticulously examines their entire supply chain, from farm to bottle, to identify and address environmental impacts. They are transparent about their sustainability practices, using data-driven metrics to measure progress and continually improve. This deep commitment extends to innovative waste management strategies, resource efficiency, and thoughtful product design. La Crosse Distilling Co isn’t just about making great spirits; it’s about creating a model for responsible distilling in the 21st century.

Defining Full Circle Sustainability at La Crosse Distilling Co.: La Crosse Distilling Co Focuses On Full Circle Sustainability

La Crosse Distilling Co. is committed to a full circle approach to sustainability, recognizing that environmental responsibility, social equity, and economic viability are interconnected. This holistic perspective guides every facet of their operations, from sourcing ingredients to managing waste. Their commitment extends beyond simply minimizing environmental impact; it aims to create a positive and lasting impact on the entire ecosystem.Full circle sustainability, in the context of a distillery, means meticulously considering the entire lifecycle of their operations.

This includes everything from the origin of their raw materials to the final disposition of their byproducts, striving to create a closed-loop system where waste is minimized and resources are maximized. It’s not just about reducing their carbon footprint, but also ensuring the well-being of their employees, supporting local communities, and generating long-term economic value.

Specific Practices Demonstrating Full Circle Sustainability

La Crosse Distilling Co. might employ various practices to embody full circle sustainability. These include utilizing locally sourced grains, employing innovative distillation techniques to maximize yield and minimize waste, and repurposing spent grains for animal feed or composting. Their water usage will be carefully managed, and they’ll actively seek out opportunities to reduce water consumption and treat wastewater to minimize environmental impact.

The company likely partners with local farmers and suppliers, fostering stronger economic ties within the community. By investing in sustainable packaging, the company can reduce their reliance on single-use plastics.

Environmental Aspects of Full Circle Sustainability

The environmental aspect of full circle sustainability is paramount. A distillery’s carbon footprint can be significantly reduced by implementing energy-efficient technologies and renewable energy sources. Careful management of water resources, from source to discharge, is crucial. Waste reduction and responsible disposal are essential, including recycling, composting, and finding alternative uses for byproducts. La Crosse Distilling Co.

likely analyzes their environmental impact using life cycle assessments, allowing them to identify and address potential environmental hazards and inefficiencies in their processes. These efforts can also improve the quality of air and water in the surrounding environment.

Social Aspects of Full Circle Sustainability

The social dimension of full circle sustainability emphasizes ethical labor practices, fair wages, and a safe working environment for employees. Supporting local communities through partnerships with farmers and suppliers, creating job opportunities, and contributing to local initiatives, are key social responsibilities. Promoting inclusivity and diversity within the company and the broader community strengthens the social fabric.

Economic Aspects of Full Circle Sustainability

Economic sustainability ensures that the business model is profitable while upholding the principles of environmental and social responsibility. La Crosse Distilling Co. might explore innovative revenue streams, like selling byproducts or partnering with local businesses for product development. Their commitment to sustainability can attract environmentally conscious consumers and investors, leading to long-term economic growth.

Key Components of the Full Circle Sustainability Plan

| Component | Inputs | Processes | Outputs |

|---|---|---|---|

| Grain Sourcing | Locally sourced grains, sustainable farming practices | Optimized distillation processes, minimizing energy consumption | High-quality spirits, minimal waste streams, reduced carbon footprint |

| Water Management | Efficient water usage, water treatment | Closed-loop water systems, minimizing water discharge | Reduced water consumption, cleaner water discharge, minimal environmental impact |

| Waste Management | Spent grains, distiller’s byproduct | Composting, animal feed, alternative uses | Reduced waste, nutrient recycling, minimized environmental pollution |

| Packaging | Sustainable materials | Eco-friendly packaging solutions | Reduced reliance on single-use plastics, decreased waste generation |

La Crosse Distilling Co.’s Supply Chain Sustainability

La Crosse Distilling Co. is committed to a full-circle approach to sustainability, extending that commitment throughout their entire supply chain. This commitment ensures that the company’s products are not only ethically sourced but also environmentally responsible from grain to glass. Their dedication to sustainable practices goes beyond just minimizing their own environmental impact; it also fosters responsible sourcing and supports the sustainability efforts of their partners.Their supply chain sustainability is a critical component of their overall sustainability strategy.

By meticulously evaluating and engaging with their suppliers, they aim to create a network of partners who share their commitment to environmental responsibility and ethical labor practices. This extends to all aspects of their operations, including the procurement of raw materials, the production process, and the distribution of their finished products.

Key Suppliers and Their Sustainability Practices

La Crosse Distilling Co. collaborates with a network of suppliers who share their commitment to sustainability. These suppliers are carefully vetted and evaluated based on their environmental, social, and ethical standards. This includes assessing their water usage, waste management, and energy efficiency, along with their labor practices and adherence to fair trade principles. For example, a key supplier might be a local grain farmer committed to sustainable agricultural practices, reducing water usage and promoting biodiversity.

Another supplier could be a packaging company focused on using recycled materials and minimizing waste.

Comparison with Other Distilleries

Compared to other distilleries, La Crosse Distilling Co. stands out for its proactive approach to supply chain sustainability. While many distilleries focus on reducing their own environmental footprint, La Crosse Distilling Co. takes a more holistic approach by integrating sustainability into their entire supply chain. This contrasts with distilleries that may have limited transparency about their sourcing practices or that prioritize profit margins over environmental concerns.

For example, some distilleries might source grains from large-scale farms with less focus on biodiversity conservation, leading to potential negative impacts on local ecosystems.

Responsible Sourcing of Raw Materials

La Crosse Distilling Co.’s approach to sourcing raw materials is rooted in the principle of responsible procurement. They prioritize locally sourced ingredients whenever possible, supporting local farmers and reducing transportation emissions. They actively seek out suppliers who use sustainable agricultural practices, minimizing their environmental footprint. This includes methods like reduced water usage, responsible pesticide application, and preserving biodiversity.

Environmental Footprint Comparison

| Raw Material Source | Environmental Footprint (Hypothetical Metrics – lower is better) | Sustainability Practices |

|---|---|---|

| Locally Grown Corn | Lower Water Usage, Reduced Transportation Emissions | Supports local farmers, promotes biodiversity |

| Genetically Modified Corn (from large-scale farms) | Higher Water Usage, Increased Transportation Emissions | Potentially lower cost, but often comes at the cost of biodiversity and water conservation |

| Locally Grown Wheat | Lower Water Usage, Reduced Transportation Emissions | Supports local farmers, promotes biodiversity |

| Imported Wheat | Higher Transportation Emissions, Potentially Higher Water Usage | May be cheaper but has a greater environmental impact |

“By prioritizing local and sustainable suppliers, La Crosse Distilling Co. is not only reducing its environmental impact but also strengthening its ties with the community and supporting local economies.”

Waste Management and Resource Efficiency

La Crosse Distilling Co. deeply understands that sustainable practices extend beyond product quality. A critical component of their full-circle approach is minimizing waste and maximizing resource efficiency throughout their operations. This commitment not only reduces environmental impact but also contributes to cost savings and long-term viability.The company actively seeks innovative solutions to minimize waste, optimize resource utilization, and reduce their environmental footprint.

Their dedication to these principles is reflected in every stage of their process, from sourcing raw materials to managing byproducts.

Waste Reduction Strategies

La Crosse Distilling Co. employs a multi-faceted approach to waste reduction, encompassing meticulous planning, proactive measures, and a culture of sustainability. This proactive approach aims to eliminate waste at its source and transform byproducts into valuable resources.

- Source Reduction: By carefully selecting ingredients and optimizing processes, La Crosse Distilling Co. minimizes the amount of waste generated in the first place. This meticulous planning is crucial to preventing waste. For example, the company meticulously assesses the nutritional composition of ingredients to identify potential waste and optimize resource allocation, which directly impacts the overall sustainability of their operations.

La Crosse Distilling Co.’s commitment to full-circle sustainability is impressive. They’re clearly thinking about the entire lifecycle of their products, from the water they use to the responsible disposal of waste. This aligns perfectly with the efforts of groups like sustaining our waters the fox wolf watershed alliance , who champion responsible water stewardship in the Fox and Wolf watersheds.

Ultimately, this dedication to sustainable practices by companies like La Crosse Distilling Co. is crucial for a healthier environment for everyone.

- Composting and Anaerobic Digestion: Organic waste, such as spent grains and other biodegradable materials, is composted and/or anaerobically digested to produce valuable compost or biogas. This process not only diverts waste from landfills but also creates a nutrient-rich soil amendment, a valuable byproduct that enhances soil fertility and reduces reliance on synthetic fertilizers.

- Recycling and Upcycling: Recyclable materials are meticulously separated and sent for recycling, contributing to a closed-loop system. The company also actively seeks opportunities to upcycle byproducts. For example, spent grains can be used as animal feed, and certain distiller’s byproducts are used as ingredients in other products, further reducing waste and promoting a circular economy.

Resource Optimization

La Crosse Distilling Co. understands that resource optimization is a crucial aspect of their sustainability goals. Their commitment to water and energy efficiency is central to their operation.

- Water Conservation: The company employs advanced water treatment and recycling systems. For instance, they reuse treated water for various purposes within the facility, significantly reducing their overall water consumption. This approach not only conserves water resources but also minimizes the strain on local water supplies. This is a crucial aspect of their environmental commitment.

- Energy Efficiency: La Crosse Distilling Co. implements energy-efficient technologies and practices throughout their facility. This includes investing in equipment that optimizes energy consumption and employing smart energy management systems. The company’s energy efficiency efforts are crucial for long-term sustainability and operational cost-effectiveness.

Waste Management Table

| Waste Stream | Management Method |

|---|---|

| Spent Grains | Composting, anaerobic digestion, animal feed |

| Packaging Materials | Recycling, source reduction |

| Wastewater | Treatment, reuse |

| Distillation Byproducts | Upcycling, other product ingredients |

| Non-Recyclable Materials | Landfilling (minimized through other methods) |

Community Engagement and Social Impact

La Crosse Distilling Co. isn’t just about crafting exquisite spirits; it’s about building a strong, vibrant community. Their commitment to full circle sustainability extends beyond the distillery’s walls, actively engaging with local partners and initiatives to foster social well-being. This engagement directly supports their environmental efforts by fostering a culture of shared responsibility and resourcefulness.La Crosse Distilling Co.’s community involvement isn’t a separate program; it’s woven into the fabric of their operations.

By partnering with local organizations and supporting educational programs, they create positive ripple effects that enhance the quality of life for everyone in the community. This interconnected approach exemplifies the core principle of full circle sustainability – where environmental stewardship and social progress are intrinsically linked.

Community Partnerships

La Crosse Distilling Co. actively collaborates with local organizations to address community needs. These partnerships extend beyond simple donations and include shared resources, expertise, and mutual support. Their relationships are not transactional but rather long-term commitments to mutual growth and well-being.

- Local Food Banks and Farmers Markets: The distillery partners with local food banks, providing ingredients or financial support to aid in their efforts. This partnership ensures a sustainable food system and reduces food insecurity in the community. The distillery also participates in local farmers markets, showcasing their products and supporting local farmers. This strengthens the local economy and promotes fresh, locally-sourced ingredients.

- Educational Initiatives: La Crosse Distilling Co. actively supports local schools and community colleges by providing educational resources and opportunities related to sustainable practices and entrepreneurship. They might offer internships or guest lectures, or donate materials for educational programs. This investment in future generations ensures a continuation of sustainability efforts in the community.

- Arts and Culture Programs: The distillery sponsors local art exhibitions, music festivals, or other cultural events. This support for the arts strengthens the cultural fabric of the community and fosters a sense of belonging for residents.

Social Impact Metrics

Quantifying the social impact of community engagement is crucial to demonstrate the effectiveness and value of these initiatives. While precise numerical data is not always readily available, qualitative data and anecdotal evidence provide valuable insights.

| Community Program | Social Impact Metrics |

|---|---|

| Local Food Banks and Farmers Markets | Increased access to fresh food, reduced food insecurity, and stronger local economy |

| Educational Initiatives | Improved access to educational resources, increased knowledge of sustainability, and fostered future leaders |

| Arts and Culture Programs | Enhanced community vibrancy, promoted local artists, and strengthened cultural identity |

“Our commitment to the community extends beyond a financial contribution; it’s about building genuine relationships and fostering a shared sense of purpose.”La Crosse Distilling Co. Management Statement.

Product Design and Packaging Sustainability

Crafting a sustainable product isn’t just about the materials; it’s about the entire lifecycle. At La Crosse Distilling Co., we believe in a full-circle approach to sustainability, and that extends to every aspect of our products, from design to disposal. We strive to minimize our environmental footprint while ensuring our consumers have access to exceptional spirits.Our packaging is meticulously considered, from the choice of materials to the design itself.

We understand that packaging plays a crucial role in the product journey and its impact on the environment. Reducing waste and promoting recyclability are paramount to our sustainable practices.

Materials Used for Packaging and Their Environmental Impact

La Crosse Distilling Co. prioritizes the use of recycled and renewable materials whenever possible. Our packaging materials are selected based on their environmental impact, with a strong emphasis on reducing reliance on virgin resources. We aim to create packaging that is not only aesthetically pleasing but also environmentally responsible.

Commitment to Reducing Packaging Waste

Our dedication to minimizing packaging waste extends to every stage of the process. From initial design to final disposal, we look for ways to streamline our packaging, reduce material use, and improve efficiency. We actively seek innovative solutions to reduce waste in every step of our packaging process.

La Crosse Distilling Co.’s commitment to full-circle sustainability is impressive. They’re clearly thinking ahead, and the future of sustainable energy looks to alternative materials like those explored in this insightful piece on the future of sustainable energy looks to alternative materials. This forward-thinking approach to sourcing and using renewable energy aligns perfectly with their overall mission of minimizing environmental impact throughout the entire production process.

Designing Products with Recyclability and Reusability in Mind

Our product design incorporates recyclability and reusability principles. This means choosing materials that are easily recycled and considering ways to make packaging reusable or adaptable to different purposes. We are continuously researching and exploring new materials and designs that enhance the recyclability of our products. We recognize that recyclability is not always straightforward, so we’re constantly looking for solutions to improve our materials’ recyclability rates.

Specific Steps to Minimize Environmental Impact of Packaging

To minimize the environmental impact of our packaging, we implement a multi-faceted approach. This includes optimizing the size and shape of packaging to minimize material usage, partnering with suppliers committed to sustainable practices, and actively exploring alternatives to traditional materials. We are also committed to ensuring that our packaging is easily identifiable for recycling.

La Crosse Distilling Co. is all about full-circle sustainability, a great model for businesses. Meanwhile, the fantastic news is that the Stevens Points Breast Care Center has received redesignation, which is a huge win for the community. This impressive commitment to healthcare quality, like La Crosse Distilling Co.’s focus on environmental responsibility, highlights the importance of ethical practices across various sectors.

Their dedication to a full-circle approach to sustainability truly inspires me. stevens points breast care center receives redesignation is a shining example of this. Ultimately, it reinforces the powerful message that businesses and healthcare providers can and should be positive forces in their communities while promoting full-circle sustainability.

Packaging Material Recyclability

| Material | Recyclability | Notes |

|---|---|---|

| Cardboard | High | Easily recycled through standard curbside programs. |

| Glass | High | Glass bottles are infinitely recyclable. |

| Aluminum | High | Aluminum is highly recyclable and requires minimal energy to reprocess. |

| Plastic | Variable | Some plastics are recyclable, others are not. We are actively working on improving our plastic packaging recyclability. |

Measuring and Reporting Sustainability Performance

Transparency and accountability are crucial in demonstrating a commitment to sustainability. La Crosse Distilling Co. recognizes the importance of quantifying its efforts and publicly sharing its progress. This allows stakeholders to understand the company’s impact and fosters continuous improvement. By meticulously tracking key metrics and reporting on performance, La Crosse Distilling Co.

strives to achieve its sustainability goals and demonstrate its dedication to environmental stewardship and community well-being.

Metrics Used to Measure Sustainability Performance

La Crosse Distilling Co. employs a multifaceted approach to measuring its sustainability performance, encompassing various aspects of its operations. The company utilizes a combination of quantitative and qualitative data to gain a comprehensive understanding of its impact. Key performance indicators (KPIs) are meticulously tracked and analyzed to evaluate progress toward goals and identify areas needing improvement.

Reporting Methods

La Crosse Distilling Co. employs various methods to report on its sustainability progress. Annual sustainability reports are a cornerstone of this process, offering a comprehensive overview of the company’s achievements and challenges. These reports often include detailed data visualizations, such as charts and graphs, to illustrate key trends and progress. Furthermore, the company utilizes its website and social media platforms to share updates on specific initiatives and achievements, fostering engagement with the public.

Monitoring and Tracking Sustainability Initiatives

A robust system for monitoring and tracking sustainability initiatives is essential for La Crosse Distilling Co. The company utilizes a dedicated sustainability team to oversee the collection and analysis of data. This team works closely with various departments to ensure alignment with sustainability goals. Regular internal audits and reviews are conducted to identify any gaps or areas for improvement.

The team collaborates with external stakeholders, such as environmental organizations and experts, to validate data and ensure accurate reporting.

Key Performance Indicators (KPIs)

To effectively track progress towards its sustainability objectives, La Crosse Distilling Co. has established a comprehensive set of KPIs. These indicators provide a clear picture of the company’s performance across different areas.

| KPI Category | KPI | Measurement Unit | Target |

|---|---|---|---|

| Water Usage | Water Consumption per Unit of Production | Liters/Kilogram | Reduce by 15% by 2025 |

| Energy Efficiency | Energy Consumption per Unit of Production | kWh/Kilogram | Reduce by 10% by 2025 |

| Waste Reduction | Total Waste Generated (by category) | Kilograms | Reduce by 20% by 2025 |

| Community Engagement | Number of Volunteer Hours | Hours | Increase by 10% by 2025 |

| Packaging Sustainability | Percentage of Recycled Content in Packaging | Percentage | Increase to 80% by 2025 |

Innovation and Future Sustainability Strategies

La Crosse Distilling Co. isn’t just chasing trends; they’re forging a path toward a truly sustainable future for the spirits industry. Their commitment to full-circle sustainability extends beyond the current practices to embrace innovative approaches and long-term strategies. This forward-thinking approach ensures the distillery’s operations remain environmentally responsible and economically viable for generations to come.This commitment involves exploring new technologies, refining existing processes, and actively engaging with the community to foster a deeper understanding of environmental stewardship.

By focusing on innovation, La Crosse Distilling Co. is setting a high bar for others in the industry to follow.

Innovative Solutions for Enhanced Sustainability

La Crosse Distilling Co. is exploring several innovative solutions to further reduce its environmental footprint. These include optimizing existing processes to minimize energy consumption, implementing cutting-edge waste management systems, and developing novel approaches to packaging and product design. The goal is to create a truly circular system where waste is minimized and resources are used efficiently.

Future Sustainability Improvements

The company’s plans for future sustainability improvements are multifaceted and encompass several key areas. These improvements will involve collaborations with research institutions, the adoption of renewable energy sources, and the implementation of new technologies for waste reduction and resource optimization.

Examples of New Technologies and Practices

La Crosse Distilling Co. is actively exploring and adopting several new technologies to enhance sustainability. These include exploring the use of anaerobic digesters to convert organic waste into biogas, which can then be used to power the distillery. They are also researching the potential of bio-based packaging materials that can be effectively recycled or composted. Furthermore, the distillery is investigating advanced water treatment technologies to optimize water usage and minimize water pollution.

Potential Future Sustainability Initiatives, La crosse distilling co focuses on full circle sustainability

| Initiative | Description | Expected Impact |

|---|---|---|

| Biogas Production from Organic Waste | Implementing anaerobic digestion systems to convert distillery waste into biogas, which can be used to power operations, reducing reliance on fossil fuels. | Significant reduction in greenhouse gas emissions, reduced reliance on traditional energy sources, and valuable resource recovery. |

| Renewable Energy Integration | Exploring options for incorporating solar, wind, or other renewable energy sources to power the distillery’s operations. | Further reduction in carbon emissions, a step toward carbon neutrality, and a demonstration of commitment to renewable energy. |

| Advanced Water Treatment Systems | Implementing advanced water purification systems to minimize water usage and ensure the discharge of clean water into the environment. | Improved water quality, reduced water consumption, and compliance with environmental regulations. |

| Bio-Based Packaging Research | Investing in research and development of bio-based packaging materials that are easily recyclable or compostable. | Reduction in reliance on petroleum-based plastics, a reduction in waste, and potential for improved product life cycle assessment. |

| Community Education Programs | Developing educational programs for the community on sustainable practices in agriculture and distilling. | Increased public awareness of sustainability, potential for community partnerships, and a broader impact on environmental stewardship. |

Epilogue

In conclusion, La Crosse Distilling Co’s dedication to full circle sustainability is impressive. Their comprehensive approach, from supply chain management to community engagement, demonstrates a commitment to a truly sustainable future for the industry. By prioritizing environmental, social, and economic factors, they are setting a high bar for other distilleries to follow. Their commitment to innovation and continuous improvement suggests a bright future for both their business and the environment.