Northwood Techs Mobile Welding Lab On the Road

Northwood tech takes to the road for training with mobile welding lab – Northwood Tech takes to the road for training with a mobile welding lab, bringing cutting-edge vocational training directly to communities. This innovative approach expands access to skilled trades, offering hands-on learning experiences in a dynamic and accessible format. The mobile lab is equipped with various welding techniques and equipment, providing students with real-world skills needed for careers in the industry.

This innovative initiative represents a forward-thinking approach to vocational training, addressing a growing demand for skilled welders.

Imagine a welding classroom that travels! Northwood Tech’s mobile lab allows students to learn valuable skills in a flexible and convenient way. It’s not just about learning welding; it’s about creating opportunities for people in diverse communities to access high-quality training. The lab is equipped with modern equipment, and experienced instructors are on hand to guide students through the process.

Introduction to Northwood Tech’s Mobile Welding Lab

Northwood Tech’s commitment to hands-on, practical training extends to their innovative mobile welding lab. This cutting-edge facility brings the latest in welding technology directly to students, fostering a dynamic learning environment that mirrors real-world applications. The lab is designed to equip aspiring welders with the skills and knowledge necessary to thrive in the industry.This mobile lab transcends the limitations of traditional classrooms, providing students with a fully functional welding environment that replicates industrial settings.

This allows for greater learning opportunities and enhances their understanding of real-world welding practices.

Key Features and Capabilities of the Mobile Lab

The Northwood Tech mobile welding lab is a state-of-the-art, self-contained unit, equipped with a range of welding equipment and techniques. This design facilitates a flexible and accessible approach to vocational training, eliminating the need for students to travel to large, fixed facilities. The portability also allows for the lab to be deployed at various locations, maximizing accessibility for learners.

Types of Welding Techniques and Equipment

The lab is outfitted with equipment for a variety of welding techniques, essential for comprehensive training. This comprehensive approach is vital for students to develop a well-rounded skillset and cater to different job requirements.

- MIG (Metal Inert Gas) welding:

- TIG (Tungsten Inert Gas) welding:

- Stick (SMAW) welding:

- Plasma cutting:

MIG welding is a popular method, characterized by its versatility and speed. The mobile lab is equipped with the necessary MIG welding machines and materials for students to practice and perfect this technique.

TIG welding is a more precise technique, often used for intricate work. The mobile lab includes TIG welding equipment, enabling students to develop expertise in this method.

Stick welding, a robust and versatile technique, is also represented in the lab’s equipment. The lab has the necessary tools and supplies for students to master this fundamental skill.

The lab’s equipment extends beyond welding to include plasma cutting tools, equipping students with the ability to cut metal with precision and efficiency.

Benefits of a Mobile Welding Lab for Vocational Training Programs

The mobile lab offers a host of advantages over traditional training methods.

- Flexibility and Accessibility:

- Real-World Simulation:

- Enhanced Practical Experience:

The lab can be brought to various locations, including schools, community centers, and even industrial sites. This increases access to training for students who might not have access to a fixed facility.

The lab’s equipment and setup closely mimic industrial environments, enabling students to experience real-world scenarios and prepare for the challenges of the workplace.

Hands-on training in a mobile setting fosters a deeper understanding of welding principles and procedures compared to purely theoretical instruction.

History of Mobile Training Labs in the Trades

Mobile training labs have become increasingly common in various trades, recognizing the importance of practical, on-site learning. This trend is driven by the need to adapt training methods to better reflect the realities of modern workplaces.

Early examples of mobile training labs often focused on specific trades, like automotive repair or HVAC. These labs provided students with the ability to practice techniques and troubleshoot equipment in simulated environments, improving their hands-on skills.

Northwood Tech’s mobile welding lab embodies this trend by providing a readily available and adaptable learning environment. It represents a significant advancement in vocational training, leveraging technology and portability to provide students with the best possible learning experience.

Training Curriculum and Methodology

The Northwood Tech Mobile Welding Lab offers a unique opportunity to revolutionize welding training, moving beyond the confines of a traditional classroom. This approach allows for hands-on learning in a variety of settings, fostering a deeper understanding of practical applications and real-world scenarios. Students benefit from a flexible and adaptable learning environment, maximizing their engagement and skill development.The mobile lab’s curriculum is designed to be flexible and adaptable, catering to diverse learning styles and equipping students with the skills needed to thrive in the dynamic world of welding.

This approach contrasts with traditional classroom settings, which can sometimes limit opportunities for practical application and real-world problem-solving.

Potential Curriculum for a Welding Course

The curriculum emphasizes a practical, project-based approach, allowing students to apply their knowledge to real-world tasks. This project-based approach is highly beneficial as it allows students to tackle complex challenges and develop essential problem-solving skills, making them better prepared for the job market.

- Fundamentals of Welding Processes: Covers the basic principles and theory behind various welding processes like MIG, TIG, and SMAW. Hands-on practice with the mobile lab’s equipment allows students to immediately see the practical application of these theories.

- Safety and Metallurgy: Thorough instruction on welding safety procedures, including personal protective equipment (PPE), and the importance of proper metal selection and preparation for optimal welding results. This module includes a detailed review of the metallurgical principles underlying the welding process, enhancing students’ understanding of material behavior during welding.

- Joint Design and Fabrication: Students learn how to design and fabricate different types of welded joints, focusing on strength, precision, and efficiency. The mobile lab’s versatility allows for the construction of various projects, giving students valuable experience in this crucial aspect of welding.

- Advanced Welding Techniques: Covers more complex welding procedures, such as pipe welding, overhead welding, and specialized welding techniques. This module focuses on challenging the students with advanced techniques to enhance their practical knowledge and expertise in the welding field.

- Troubleshooting and Quality Control: Students learn to identify and rectify common welding defects, and understand quality control measures for ensuring weld integrity. The mobile lab’s equipment allows students to examine different weld defects and analyze their causes and solutions.

Comparison with Traditional Classroom Training

Traditional classroom training often relies heavily on theoretical instruction, while the mobile lab approach emphasizes practical application. This difference is crucial because hands-on experience is invaluable in welding. The mobile lab provides immediate feedback and allows students to practice and refine their skills in a safe and controlled environment.

- Hands-on Experience: The mobile lab offers a significant advantage by providing immediate and continuous hands-on experience. Students are actively engaged in the learning process, rather than simply absorbing theoretical knowledge.

- Flexibility and Adaptability: The mobile lab’s ability to travel to different locations offers greater flexibility, allowing for practical training in diverse environments and industries.

- Real-world Applications: Welding in the mobile lab is often project-based, mirroring real-world scenarios. This approach ensures students develop a deep understanding of how their skills translate to actual work applications.

Hands-on Experience

The mobile lab’s key strength is its hands-on nature. Students are not just observers; they are active participants in the learning process. This direct engagement fosters a deeper understanding and retention of concepts, while also building practical skills quickly.

Learning Styles Catered To

The mobile lab’s flexible format caters to different learning styles. The emphasis on practical application appeals to kinesthetic learners, while the interactive nature of the lab engages visual and auditory learners as well. The diverse learning environment also supports collaborative learning among students.

Training Modules and Learning Objectives

| Training Module | Learning Objectives |

|---|---|

| Fundamentals of Welding Processes | Understand the basic principles of various welding processes and their applications. Develop proficiency in fundamental welding techniques. |

| Safety and Metallurgy | Master safety procedures in welding environments. Understand metallurgical principles relevant to welding. |

| Joint Design and Fabrication | Design and fabricate various welded joints with precision and efficiency. |

| Advanced Welding Techniques | Apply advanced welding techniques to complex projects, such as pipe welding and overhead welding. |

| Troubleshooting and Quality Control | Identify and rectify welding defects. Apply quality control measures to ensure weld integrity. |

Logistics and Accessibility

The Northwood Tech Mobile Welding Lab is designed for maximum accessibility, bringing expert-level training directly to communities and schools. This flexible approach allows us to reach students who might not have access to traditional welding programs, fostering a wider skill development network. Crucially, this mobility requires careful planning and execution to ensure smooth operations and effective learning.The mobile lab’s design and logistics are paramount to its success.

We need to consider not only the equipment’s transport but also the training materials and personnel required for each deployment. This includes the lab’s set up and tear down, transportation, and necessary safety precautions.

Transportation and Logistics

Planning the mobile lab’s travel schedule is crucial. We need to consider factors like vehicle maintenance, driver availability, and potential road closures or weather delays. This requires a detailed route planning and logistical framework, including the use of GPS tracking and real-time updates for the lab’s location. The lab’s size and weight require a specialized vehicle with appropriate load capacity and safety features.

Accessibility for Students and Community Members

Accessibility extends beyond physical location. The lab’s scheduling must be accommodating to students’ schedules and available community spaces. This includes offering training sessions during flexible hours and accommodating various student needs, like providing translation services if necessary. The training curriculum and materials must also be easily understood and adaptable to different learning styles.

Adapting Training Materials

Adapting training materials to a mobile format requires careful consideration. The mobile lab’s compact size may limit the space available for certain exercises. We must ensure that the training materials are adaptable and that the learning outcomes remain consistent. Modular training units can be a great solution.

Partnerships with Local Businesses

Strategic partnerships with local businesses can greatly enhance the mobile lab’s impact. Businesses could provide mentorship, equipment access, or even sponsor training events. This collaborative approach allows for greater exposure to real-world welding applications. For example, a local fabrication shop might offer internships or shadowing opportunities.

Scheduled Deployments

The following table Artikels potential locations and dates for the mobile lab’s scheduled deployments. These dates and locations are tentative and subject to change based on scheduling and logistical considerations.

| Location | Date | Description |

|---|---|---|

| Central High School | October 26th – 28th | Introductory welding course for high school students |

| Northwood Community Center | November 9th – 11th | Advanced welding techniques for adults |

| Westside Technical Institute | December 7th – 9th | Welding for construction apprenticeship program |

Impact and Reach of the Mobile Welding Lab

The Northwood Tech Mobile Welding Lab isn’t just a traveling workshop; it’s a catalyst for change in welding education. It brings cutting-edge training directly to communities that might not otherwise have access to high-quality vocational programs, fostering a new generation of skilled welders. This innovative approach directly impacts student engagement, learning outcomes, and long-term career prospects.The mobile lab’s reach extends far beyond the typical classroom setting, empowering individuals in underserved areas to acquire essential skills.

By removing geographical barriers, we are democratizing access to vital training, enabling them to pursue careers in a high-demand field. This program demonstrates a clear commitment to creating equitable opportunities in technical education.

Positive Impact on Student Engagement and Learning

The hands-on nature of the mobile lab fosters a dynamic and engaging learning environment. Students are more actively involved in the training process, leading to improved comprehension and retention of the material. The practical, real-world application of welding techniques within the mobile lab setting enhances learning and instills confidence in students. This is particularly evident in the enthusiastic participation and focused attention observed during demonstrations and hands-on exercises.

The mobile lab’s modern equipment and interactive learning approach create an atmosphere that sparks a deeper interest in the craft, leading to increased motivation and a desire to excel.

Expanding Access to Welding Training Programs in Underserved Communities

The mobile welding lab directly addresses the disparity in access to vocational training in underserved communities. By bringing the lab to these locations, Northwood Tech removes the financial and logistical hurdles that often prevent individuals from pursuing welding careers. These communities often lack access to state-of-the-art facilities and qualified instructors. The mobile lab provides a cost-effective and convenient way to deliver comprehensive welding training, empowering individuals in these communities to develop valuable skills and achieve economic self-sufficiency.

The impact is particularly pronounced in rural areas where traditional vocational centers may not exist.

Long-Term Career Outcomes for Mobile Lab Trainees

The welding skills acquired through the mobile lab program translate directly into high-demand job opportunities. Graduates are highly sought after by employers across various industries, including construction, manufacturing, and energy. The rigorous training in the mobile lab prepares students to enter the workforce confidently and equipped with the technical skills required for success. The demand for skilled welders remains robust, guaranteeing excellent career prospects for graduates of the program.

Northwood Tech’s mobile welding lab is hitting the road, providing valuable hands-on training for aspiring welders. This innovative approach is crucial for a future where sustainable energy sources like wind and solar require specialized skills in working with alternative materials, like those explored in the future of sustainable energy looks to alternative materials. The mobile lab’s adaptability ensures practical learning opportunities are accessible, no matter the location.

This initiative ensures students gain the skills needed to build a greener future, a vital component for Northwood Tech’s commitment to workforce development.

Success Stories of Graduates

Numerous graduates of the mobile welding lab program have achieved remarkable career milestones. One example is Sarah Miller, who used the skills gained through the mobile lab to establish her own successful welding business. Another graduate, David Johnson, secured a high-paying position as a welder in a local manufacturing plant after successfully completing the program. These success stories highlight the tangible benefits of the mobile welding lab program and its impact on the lives of those who participate.

Comparison of Student Outcomes

| Characteristic | Mobile Welding Program | Traditional Classroom Program |

|---|---|---|

| Student Engagement | High, due to hands-on learning and modern equipment | Variable, dependent on instructor and classroom dynamics |

| Access to Training | Increased access to underserved communities | Limited to geographic proximity of traditional centers |

| Career Outcomes | High demand for graduates, leading to job placement and entrepreneurship | High demand for graduates, but potential geographical limitations for placement |

| Student Retention Rate | High, driven by the interactive and engaging learning environment | Variable, dependent on course structure and engagement factors |

Future Considerations and Innovations

The Northwood Tech mobile welding lab represents a significant step forward in accessible vocational training. To maximize its impact and remain relevant in the ever-evolving world of welding, continuous improvement and innovation are crucial. This section explores potential enhancements to the lab’s design, equipment, and outreach strategies.

Potential Improvements to Mobile Lab Design and Equipment

The current design of the mobile welding lab, while functional, can be optimized for greater efficiency and safety. Consideration should be given to improved ventilation systems, particularly for enclosed areas, to mitigate the risks associated with welding fumes. Additional storage space for equipment and supplies, and better organization of the work areas, will enhance workflow and minimize potential hazards.

Upgrading the lab’s exterior to include features like reinforced flooring, secure storage compartments, and weatherproofing will increase its overall longevity and usability in various climates.

New Technologies for Incorporation into the Mobile Lab

Technological advancements in welding offer opportunities to enhance the mobile lab’s capabilities. Incorporating robotic welding systems or advanced 3D modeling software could provide students with cutting-edge skills and exposure to modern techniques. Integrating digital welding simulators, which allow for realistic practice without the hazards of hot metal, could greatly enhance the learning experience. Wireless connectivity and cloud-based learning platforms can support remote access to resources and expert guidance, further expanding the lab’s reach and flexibility.

Innovative Ways to Promote and Market the Mobile Lab

Innovative marketing strategies are essential to attract potential students and partners. Utilizing social media platforms, creating engaging videos showcasing the lab’s capabilities and the training programs, and partnering with local schools and community organizations can generate significant interest. Collaborating with vocational schools and industry professionals to develop joint training programs can broaden the lab’s appeal and create a pipeline of skilled workers.

Developing a comprehensive website and mobile app will allow for easy access to information about the lab, schedules, and training opportunities.

A Future-Proof Mobile Welding Lab

A future-proof mobile welding lab should seamlessly integrate cutting-edge technologies while maintaining a robust and safe design. This would include a modular design, enabling adaptability to future technologies and changing training needs. The lab should be equipped with advanced welding equipment, including robotic systems, plasma cutters, and advanced digital controls. Wireless connectivity and cloud-based resources would ensure accessibility and collaboration with remote experts.

Northwood Tech’s mobile welding lab is hitting the road, offering hands-on training to students. This innovative approach is great for reaching a wider range of potential trainees, and it’s all about bringing the learning experience directly to them. It’s a really cool concept, reminiscent of a more immersive and flexible learning model, like exploring different approaches to education, which directly connects to the exciting possibilities of learning and development.

This is a fantastic way to expand opportunities in the welding field, especially considering the current job market demand, which aligns with Northwood Tech’s commitment to providing high-quality vocational training. To see more about how different approaches to education are impacting learning, check out this great article: Hello world!. The mobile lab really is a game-changer for accessible and practical welding education.

Safety features like enhanced ventilation systems and automatic emergency shut-offs should be integrated for student and staff well-being. Moreover, a modular layout will allow for easy reconfiguration of the workspaces for different types of welding training.

Potential Partnerships with Local Businesses or Educational Institutions, Northwood tech takes to the road for training with mobile welding lab

Strategic partnerships can significantly amplify the impact of the mobile welding lab. These partnerships can provide valuable resources, mentorship, and real-world application opportunities for students.

| Partner Type | Potential Benefits | Example |

|---|---|---|

| Vocational Schools | Shared training resources, joint curriculum development, cross-enrollment opportunities | Local high schools or community colleges |

| Welding Companies | Hands-on training, internships, apprenticeships, equipment donation, industry experts for guest lectures | Fabrication shops, construction companies |

| Equipment Suppliers | Equipment donations, training sessions, discounts, maintenance support | Welding equipment distributors |

| Government Agencies | Funding opportunities, grant applications, collaboration on vocational training initiatives | Local workforce development boards |

Visual Representation

The mobile welding lab isn’t just a container; it’s a dynamic training hub on wheels. Its visual representation captures the essence of hands-on learning, showcasing the lab’s versatility and impact on students’ skill development. We’ll delve into compelling images, highlighting the lab’s interior layout, deployment at various locations, the diversity of students using it, and the practical projects they undertake.

Mobile Welding Lab in Action

Imagine a vibrant scene: Northwood Tech’s mobile welding lab, parked in a bustling community center. Students, clad in safety gear, are intently focused on their welding tasks. A skilled instructor guides them, providing personalized support and ensuring proper technique. Sparks fly, creating a captivating display of controlled energy. The image emphasizes the practical and hands-on nature of the training, ensuring students gain valuable experience in a real-world setting.

Interior Layout of the Mobile Lab

The mobile lab’s interior is meticulously designed for efficient training. It features various workspaces, each optimized for a specific welding task. A central welding bay accommodates multiple welding stations, equipped with state-of-the-art welding equipment and safety features. Adjacent spaces are dedicated to material preparation, allowing students to practice cutting, shaping, and preparing metal pieces before welding. Storage areas are strategically placed to maximize space and keep materials organized.

The image clearly displays the division of the interior spaces, highlighting the practical aspects of the training setup.

Deployment at a New Location

The image depicts the mobile lab smoothly transitioning to a new location. A crane is lifting the trailer onto a designated platform. Construction workers and Northwood Tech staff are diligently preparing the site for operation. The image showcases the ease of deployment and the mobile lab’s adaptability to different environments. The scene is well-organized, with a backdrop of the new location, creating a sense of community engagement and accessibility.

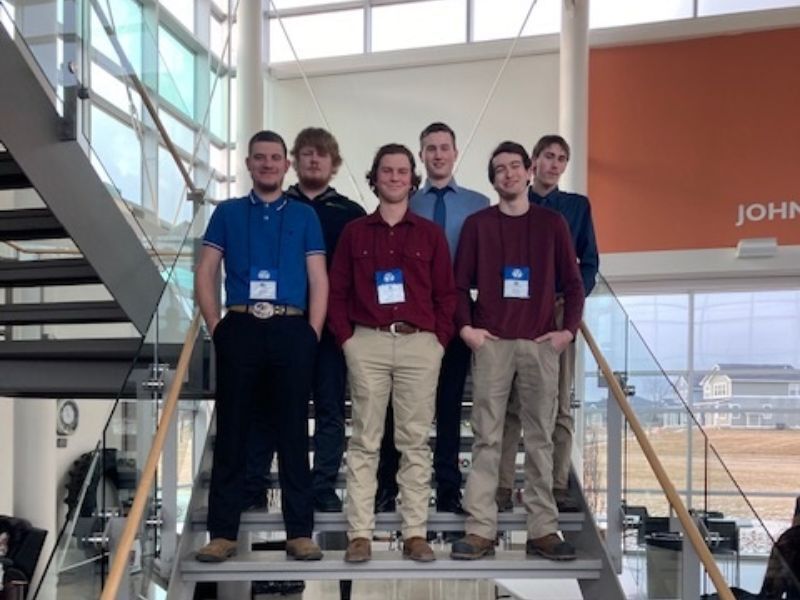

Diversity of Students

The image portrays a diverse group of students actively participating in the welding program. Students of different ethnicities, genders, and backgrounds are engaged in welding activities. This visual representation emphasizes the lab’s inclusivity and accessibility to a broad range of individuals, promoting diversity in the skilled trades. The image highlights the welcoming and supportive environment of the program, encouraging participation from all backgrounds.

Students Working on Welding Projects

A series of images captures students diligently working on various welding projects. One image shows students crafting intricate metal designs, while another showcases students constructing functional components for a larger project. These visuals underscore the range of skills students develop within the mobile lab. The images demonstrate the progressive nature of the training, showcasing how students advance from basic to more complex projects, thereby fostering a sense of accomplishment and mastery.

Final Conclusion: Northwood Tech Takes To The Road For Training With Mobile Welding Lab

Northwood Tech’s mobile welding lab is a testament to their commitment to providing accessible and high-quality vocational training. This initiative not only enhances student engagement but also significantly expands opportunities for individuals in underserved areas. The lab’s adaptability and potential for partnerships with local businesses are key components in fostering future success for students. This innovative approach has the potential to revolutionize the future of vocational education, empowering students to enter the workforce prepared for high-demand careers.